In addition to its employees and the wealth of expertise they bring, one of IFPEN’s strengths is its equipment pool supporting research activities. These resources are often developed or adapted in-house since they address specific needs. They cover different scales, ranging from a laboratory assembly to pre-industrial pilot, and make it possible to focus efforts on the entire TRL spectrum: from the understanding of phenomena through to the development and integration of industrial solutions, via the creation of methodologies adapted to project needs.

CUTTING-EDGE RESOURCES AVAILABLE

For example, the understanding of fluidized flows is gained from the microscopic scale, using laboratory microfluidics tests, through to the industrial scale, with Lyre loop flow tests conducted in real conditions, via the modeling of the physical phenomena that characterize fluid flows, either alone or in interaction with solids or structures, in or around varied geometries.

Similarly, for the understanding of the structure of materials, resources are available from the elementary scale – with, in particular, an elemental analysis laboratory, an X-ray scanner for homogeneity characterization, two laboratories dedicated to the characterization of the morphology and mechanical properties of solids – through to industrial-scale facilities, such as tensile and flexion stress test benches.

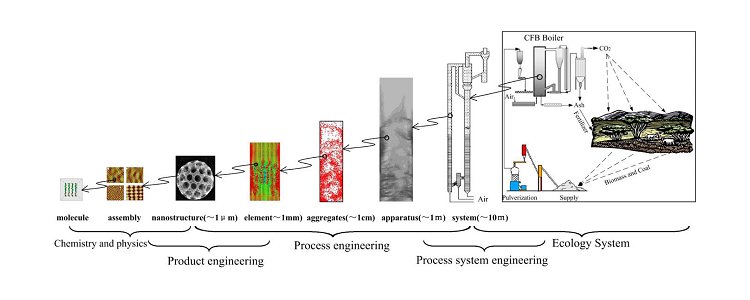

The change in scale between the laboratory and industrial application tests in real conditions is vital to technology transfer in the field of chemistry. It is for this reason that IFPEN played an active role in the Sysprod “Multiscale systemic approach for industrial production processes” project, alongside academic and industrial partners from Lyon’s chemistry valley. The project, organized around two fields - catalysis for eco-efficient processes and polymer materials - led to the introduction of advanced tools in the form of platforms dedicated either to discovery (TRL 1 to 3) or scale change (TRL 4 to 6). The latter are also available to industrial players via the Axel’One platform.

Moreover, to develop levers for understanding fundamental research problems, IFPEN also contributes to pooled equipment, such as EquipEx (facilities for excellence), and joint LabEx-type laboratories, and uses large-scale facilities via access agreements.

For example, the framework agreement with SOLEIL Synchrotron was renewed for a period of four years in 2021. This very large research infrastructure (TGIR) at the Saclay platform gives IFPEN access to advanced tools for the detailed characterization of materials in the fields of energy and processes and the dynamic monitoring (in situ or operando) of mechanisms at work within materials. Find out about some of the advances made possible by this TGIR.

Similarly, in 2018, thanks to an access agreement concerning a GC-ICP/MS/MS instrument at the Institut des sciences analytiques (Institute of Analytical Sciences) in Lyon, a major advance was made possible in the field of the speciation of organochlorides in reformates. Detection limits in the region of 40 ppb of elemental chlorine per compound were achieved, i.e., around ten times smaller than other existing methods.

LABEX EXCELLENCE LABORATORY

iMust

IFPEN is active in the excellence laboratory iMust “Institute for Multi-scale Sciences and Technologies”, hosted by the University of Lyon Comue. The active involvement in this laboratory reinforces the long-standing collaboration with this partner and enhances the quality of research conducted in Lyon region.

The iMust project aims to establish an excellence center in the fields of materials, processes and eco-technologies, for which multidisciplinary research integrating physics, chemistry and engineering is essential. IFPEN brings its expertise in the fields of catalysis and catalytic processes, numerical models and simulations as well as instrumentation and characterization.

Positively evaluated by an international jury in 2019, the scientific and technological results obtained by this Labex, as well as the impact of its activities on scientific communities, resulted in its renewal for a period of 5 years.

EQUIPEX FACILITIES FOR EXCELLENCE

NanoimagesX

IFPEN is one of the users of the NanoimagesX EquipEx facility for excellence, dedicated to very high-resolution 3D imaging. This investment for the future at the Synchrotron SOLEIL, backed by 16 public research and industrial partners, involved the design, construction and commissioning of a beamline dedicated to full-field tomography and microscopy.

Known as ANATOMIX (Advanced Nano-Tomography and Imaging with Coherent X Rays) and operational since 2018, this beamline is unique in its kind due to its high degree of sensitivity and resolution capacity, an invaluable addition to other European facilities. Its two experimental micro- and nanotomography stations, which IFPEN started to use in its projects at the end of 2019, make it possible to obtain highly intense and coherent X-ray beams across a range of energy, thereby providing access to a variety of cutting-edge imaging solutions. This beamline offers optimal conditions for studying the internal structure of complex three-dimensional objects and systems with a spatial resolution as low as 80 nm, and for studying dynamic evolutions with speeds of up to one tomography scan per second.

Corrosion test loop

In 2018, for the purposes of research conducted by the CORRTEX (Corrosion Research and Technical Expertise) consortium, IFPEN and the French Corrosion Institute signed an 8-year agreement with Axel’One relating to access to a corrosion test loop. Designed to simulate a variety of corrosive environments, it reproduces extremely harsh operating conditions to test the corrosion resistance of various materials, understand the origin of corrosion damage, predict operating performances and detect corrosion at an early stage.

DATAIA CONVERGENCE INSTITUTE

IFPEN’s research dedicated to data sciences is also supported by the DataIA Convergence Institute within the framework of scientific challenge 4, “the optimum processing of large volumes of experimentation and simulation data”. This institute, of which IFPEN is a founding member, brings together 12 partners (universities, research institutes and graduate schools) to focus on the scientific and technical challenges related to data sciences and associated socio-economic issues.

ECCSEL PROGRAM

IFPEN is also a member of the ECCSEL (European Carbon dioxide Capture and StoragE Laboratory infrastructure) consortium, bringing together leading European laboratories in the field of CO2 capture and storage. As such, IFPEN contributes its expertise and test facilities to analyze and interpret geochemical gas data.