Bio-based chemistry is chemistry in which fossil resources are partially or completely replaced by resources derived from biomass. In particular, it helps limit reliance on fossil resources for the production of certain types of products and reduces the environmental footprint of these products.

- What is bio-based chemistry?

- An emerging sector

- A sector that addresses current challenges

- Challenges to be overcome

- The economic development of the sector

What is bio-based chemistry?

Differences between green chemistry and bio-based chemistry

“Green chemistry” (or “sustainable chemistry”) is a form of chemistry that aims to be safer and more environmentally-friendly, in accordance with the principles of sustainable development. Green chemistry generally involves the application of 12 principles, aimed at promoting a reduction in environmental impacts: design of safer chemicals, waste prevention, improved energy efficiency, or the use of renewable raw materials, for example.

Bio-based chemistry is a form of green chemistry, with the specific characteristic that it uses a raw material that is necessarily derived from biomass (plants, wood, plant products, algae, etc.) and is therefore renewable, rather than a fossil resource such as oil, coal or natural gas.

The end products are then described as being “bio-based” since they are derived from biomass. The incorporation of bio-based chemistry products can be via existing sectors or involve the creation of new chains and processes.

The main plant resources currently used by industry are as follows:

- starchy plants (wheat, corn, potato) and sugar-containing crops (beetroot);

- oleaginous crops (with a high oil content): rapeseed, sunflower, soybean, etc. ;

- lignocellulosic plants (with a high cellulose content): wood, straw, flax, hemp, etc. ;

- resinous trees: pine, fir;

- plants containing active substances, essential oils, fragrances, etc.

This conversion is conducted in biorefineries, industrial facilities where processes are implemented to separate the various components of the plant mass - which may be a food resource or otherwise - in order to obtain chemical products that can be used either directly or in the composition of end materials (such as plastics, for example).

Les biocarburants

Like plant chemistry products, biofuels are also derived from organic plant matter, after processing in a biorefinery.

>> Find out more about biofuels

The various types of chemical conversion will depend on the nature of the biomass used:

- for oils, lipochemistry or oleochemistry is used;

- while glucose, starch and cellulose will be processed via sugar chemistry;

- plant matter can also be converted into synthetic gas via thermochemistry;

- wood chemistry can be used to convert the components of wood into substances such as cellulose, hemicellulose and lignin, which can then be turned into materials or products via sugar chemistry or more traditional chemical processes.

Today, bio-based products are used in the composition of materials in numerous different sectors, including:

- construction (insulating materials, paints, adhesives),

- the automotive sector (components, oils, lubricants);

- hygiene products (household cleaning products, laundry products, toiletries, etc.);

- packaging;

- cosmetics.

Bioplastics

The term “bioplastics” actually groups together two categories of materials: bio-based plastics and biodegradable plastics of fossil origin. Bioplastics have the same properties as conventional plastics, while offering additional advantages in terms of environmental footprint, waste management or composting possibilities.

An emerging sector

The European Commission estimates that bio-based products and biofuels represent an annual turnover of around 57 billion euros and 300,000 jobs. It anticipates an annual growth rate of 20% in the coming years for bio-based products in terms of their proportion within total chemical sales.

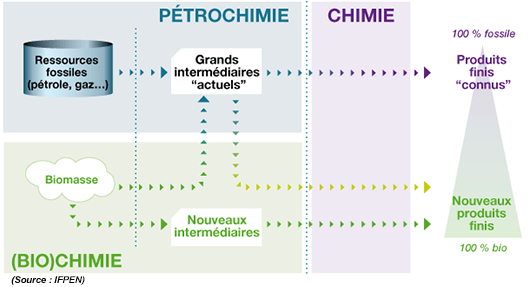

There are two main approaches for the development of bio-based chemistry:

- The substitution of petrochemical intermediate substances by bio-based substances with similar functionalities. The final material will remain the same. This approach enables bio-based products to be easily integrated into existing sectors, to produce either 100% bio-based or partially bio-based products.

- The creation of new products, new end substances with innovative functionalities. This approach makes it possible to obtain a fully plant-based product, but its development is more risky in economic terms and involves a higher cost since it usually concerns a disruptive technology that will require the development of an entire industrial sector.

These two approaches are what make plant-based chemistry so innovative, both as an alternative to fossil-derived products and because it enables the creation of substances with brand new functionalities.

The European Commission anticipates an annual growth rate of 20% in the coming years for bio-based products in terms of their proportion within total chemical sales.

A sector that addresses current challenges

New outlets for agriculture

The bio-based products sector opens up new opportunities for the farming world.

France has a well established sector of first-stage processing industries for agricultural products. These industries convert plant-derived raw materials into products (starches, oils, sugars, etc.) that can then be used in the context of plant chemistry. Along with bio-based materials, this field represents an outlet for 15% of their annual production, on average. This proportion has been increasing since 2005, and partially compensates for the fall in demand on the part of traditional sectors, such as paper. Remaining production is destined for food, energy (biofuel) and pharmaceutical uses.

The majority of plant-derived raw materials used in France in the context of bio-based chemistry are produced locally, apart from oils, a significant proportion of which are produced using tropical plants (palm, copra, castor oil) .

A response to the challenges of sustainable development

Bio-based chemistry addresses various challenges associated with sustainable development.

In particular, it can be used to replace substances derived from fossil resources such as oil and natural gas with substances derived from biomass. This diversification of raw materials reduces our reliance on fossil resources, as well as the impact of the latter’s price volatility.

Bio-based products also make it possible to reduce the carbon footprint of industry and consumers. That is because plants capture CO2 via photosynthesis. Bio-based products are then made using this carbon captured by biomass, helping to reduce the amount of fossil CO2 emitted into the atmosphere.

Bio-based product: recyclable or biodegradable?

The fact that a product is bio-based does not necessarily mean that it is recyclable or biodegradable.

Bioplastics with a molecular structure identical to that of traditional plastics (such as polyethylene, polyethylene terephthalate or PVC) can be recycled using existing treatment processes. For materials that cannot be handled in these sectors, other specific recycling processes will need to be envisaged.

Finally, some bio-based products are biodegradable and can undergo composting or methanization.

A growing demand on the part of society

The use of bio-based products meets a growing demand on the part of consumers for products that are not harmful to health or the environment.

This is also accompanied by a strong demand for transparency with respect to the composition of products. Traceability, labeling and certification processes exist or are in the process of being developed, helping to address this challenge.

New properties

Bio-based products can be used to create materials with new properties (transparent, resistant, lightweight, etc.). They thus meet a growing need on the part of chemical industries and manufacturers to expand their raw material range and market innovative products.

Challenges to be overcome

While the development of plant chemistry addresses some economic, environmental and societal issues, the sector also has a number of other challenges to overcome. These include the availability of the resource and the competitiveness of the products.

The availability of plant biomass resources and competition with other uses

Plant biomass is a resource that is in high demand: it addresses needs in terms of food, it can be an energy source, it can be used to fertilize the soil and also to store carbon. Competition between plant chemistry and these other uses for biomass may represent an obstacle to the sector’s development.

Moreover, climatic conditions and water management can have an impact on the availability of biomass and generate market pressures. The significance of these parameters could increase with climate change and the rising world population.

The joint construction of the sector with biomass producers (agricultural and forestry sectors) and the application of circular economy principles (production of bio-based substances derived from food crop residues) may represent the keys to good management of this resource.

The issue of bio-based product competitiveness

The fact that a product is bio-based is not necessarily a competitive advantage in itself, since other factors play a key role in their competitiveness.

Price is the first factor for competitiveness. The overall cost of bio-based products compared to those derived from the petrochemical industries is difficult to assess, particularly since oil prices remain highly volatile. In fact, production costs for some bio-based products may be several times higher than those for conventional petrochemical processes, whereas for others the production costs will be comparable. In the case of bio-based plastics, for example, production costs are generally higher than for those made using fossil-derived substances, representing a major obstacle to their development.

One of the decisive factors affecting price is the fact that the bio-based product can be produced within existing industrial facilities, the latter having demanded significant investments. In addition, this adaptability helps maintain existing industrial systems, while at the same time offering new opportunities (job creation, new markets). New production chains specific to the new bio-based products are developed in parallel, providing they are economically and technically viable.

Variations in raw material costs - particularly the cost of oil compared to that of plant raw materials - will also have an impact on the competitiveness of bio-based products.

Furthermore, some bio-based products - particularly first-generation products (starch, PLA, PHA) - cannot reproduce the mechanical properties (water or temperature sensitivity) required for their commercial use (in bottle form, for example).

The economic development of the sector

Bio-based product sectors are highly complex. As we have seen above, there are a multitude of biomass-derived resources that can be used, requiring conversion processes and hence biorefineries, which may be very different in nature.

In addition, these sectors involve a variety of players at every stage, from biomass production, via the processing phases, right through to distribution of the finished product(s). This sector also covers a broad diversity of end products and applications.

Today, bio-based chemistry represents only a small part of the organic chemistry sector as a whole: only 1 to 2 million tonnes out of some 400 million tonnes produced per year . But projections indicate that this proportion is tending to increase: it is estimated that it will represent around 15 million tonnes by 2030. In addition, some biomass-derived materials, such as hemp or flax fibers, can be directly used on the market as direct substitutes for polyester fibers (which are derived from oil), meaning that they are developing more quickly.

For bioplastics, production is still very limited, although it has increased sharply. The proportion of bioplastics in world plastics production remains less than 1%.

The majority of bioplastics are produced in Asia (55%), followed by Europe (19%), North America (16%), South America (9%) and Oceania (1%) .

Like plant chemistry products, biofuels are also derived from organic plant matter, after processing in a biorefinery.

The demand for bio-based products is likely to continue to rise in the coming years. Bio-based chemistry is an emerging industrial activity, offering significant development potential. It addresses a consumer demand, as well as the requirements of the agro-industrial sector, the chemical industry (diversification), and the agriculture sector. The main challenge is to obtain major chemical intermediates, requiring access to suitable industrial facilities and a bio-based raw material that does not compete with food. IFPEN is positioned as a developer of technologies for integrated biorefineries and as a catalyst for the emergence of new industrial sectors relating to the energy transition.

"Bio-based chemistry is an emerging industrial activity, offering significant development potential."

Slavik Kasztelan, Manager of the Biomass to chemicals program.

Our expertise >

Our expertise >