21.10.2020

3 minutes of reading

The four-year Dinamx “Demonstration and innovative applications of the DMX™ process” project* has been launched by partners IFPEN, Total Refining & Chemicals and ArcelorMittal France. Coordinated by Axens, the objective is to demonstrate the DMX™ process designed to capture carbon dioxide from blast furnace gases and extend its scope of application to other types of emitters in order to reduce CO2 emissions in France.

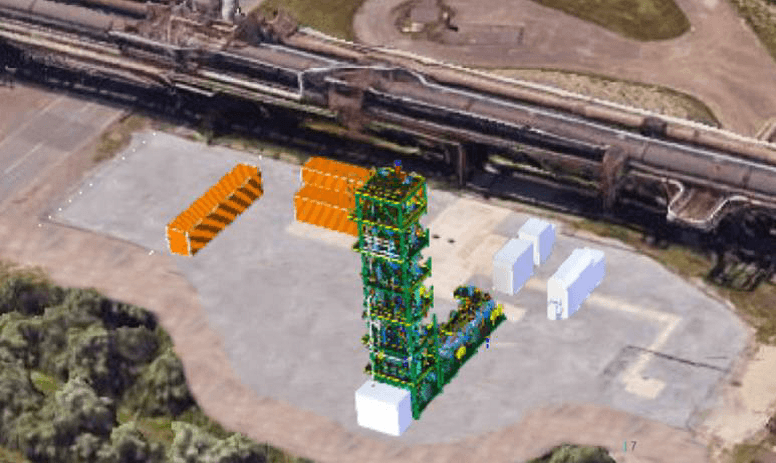

The process will initially be demonstrated on the pilot unit built for the European H2020 3D project at ArcelorMittal’s site in Dunkirk, with a capacity of 0.5 t CO2/h. Other applications will be examined with a view to validating the potential benefits of the process for cement works, glassworks, urban heating and electricity production from biomass.

DMX™, a competitive decarbonization technology

The result of a decade of research, the DMX™ process, developed by IFPEN and marketed by Axens, uses a solvent for separating CO2 via absorption with a high capture capacity. Made up of a mixture of 2 amines in aqueous solution and initially forming a single phase, this so-called demixing solvent splits into two phases when in contact with flue gases laden with CO2. Since the CO2 is concentrated in one of the two phases, this significantly reduces the volume to be treated during the energy-intensive phase, i.e., solvent regeneration by steam injection at a temperature of 160°C.

This competitive technology should make it possible to reduce the cost of CO2 capture by 30% compared to more traditional processes and have an energy penalty of below 2.3 GJ/tCO2 for the capture of at least 90% of emissions from a steelworks or coal-fired power plant. Every ton of CO2 “avoided” will cost between 30 and 40 euros, compared with 50 euros with existing methods. Moreover, the CO2 produced is extremely pure (99.7%) and under pressure (up to 7 bara), which facilitates the subsequent pressurization required to transport it either by boat or pipelines.

*funded by Ademe following the Eco-Efficient Industry call for projects launched within the framework of the “Démonstrateurs et Territoires d’Innovation de Grande Ambition” (Ambitious Demonstrators and Innovative Territories) initiative incorporated in the French Investments for the Future program

Reminder

CO2 capture and storage (CCS) technologies are crucial in order to achieve COP21 objectives. According to the IEA, they are set to account for 9% of the CO2 emission reductions required by 2050 in order to reduce global warming to 2°C by 2100. In France, the biggest industrial CO2 emitters are the electricity production sector (23 Mt), urban heating and other sectors (23 Mt) and the steel industry (18 Mt).

>> To find out more : CO2 capture, utilization and storage