28.05.2019

5 minutes of reading

Dunkirk, May 27, 2019

A consortium of 11 European stakeholders including ArcelorMittal, Axens, IFP Energies nouvelles (IFPEN) and Total, is launching a project today to demonstrate an innovative process for capturing CO2 from industrial activities—the DMX™ project. It is part of a more comprehensive study dedicated to the development of the future European Dunkirk North Sea Capture and Storage Cluster.

The “3D” project (for DMX™ Demonstration in Dunkirk) is part of Horizon 2020, the European Union’s research and innovation program. The project has a 19.3-million-euro budget over 4 years, including 14.8 million euros in European Union subsidies. Coordinated by IFPEN, the “3D” project brings together other 10 partners from research and industry from 6 European countries: ArcelorMittal, Axens, Total, ACP, Brevik Engineering, CMI, DTU, Gassco, RWTH and Uetikon.

The objective is threefold:

- Demonstrate the effectiveness of the DMX™ process on a pilot industrial scale.

The pilot, designed by Axens, will be built starting in 2020 at the ArcelorMittal steelworks site in Dunkirk and will be able to capture 0.5 metric tons of CO2 an hour from steelmaking gases by 2021.

The DMXTM process, a patented process stemming from IFPEN’s Research and to be marketed by Axens, uses a solvent that reduces the energy consumption for capture by nearly 35% compared to the reference process. Additionally, using the heat produced on site will cut capture costs in half, to less than 30 euros per metric ton of CO2.

- Prepare the implementation of a first industrial unit at the ArcelorMittal site in Dunkirk, which could be operational starting in 2025. It should be able to capture more than 125 metric tons of CO2 an hour, i.e. more than one million metric tons of CO2 a year.

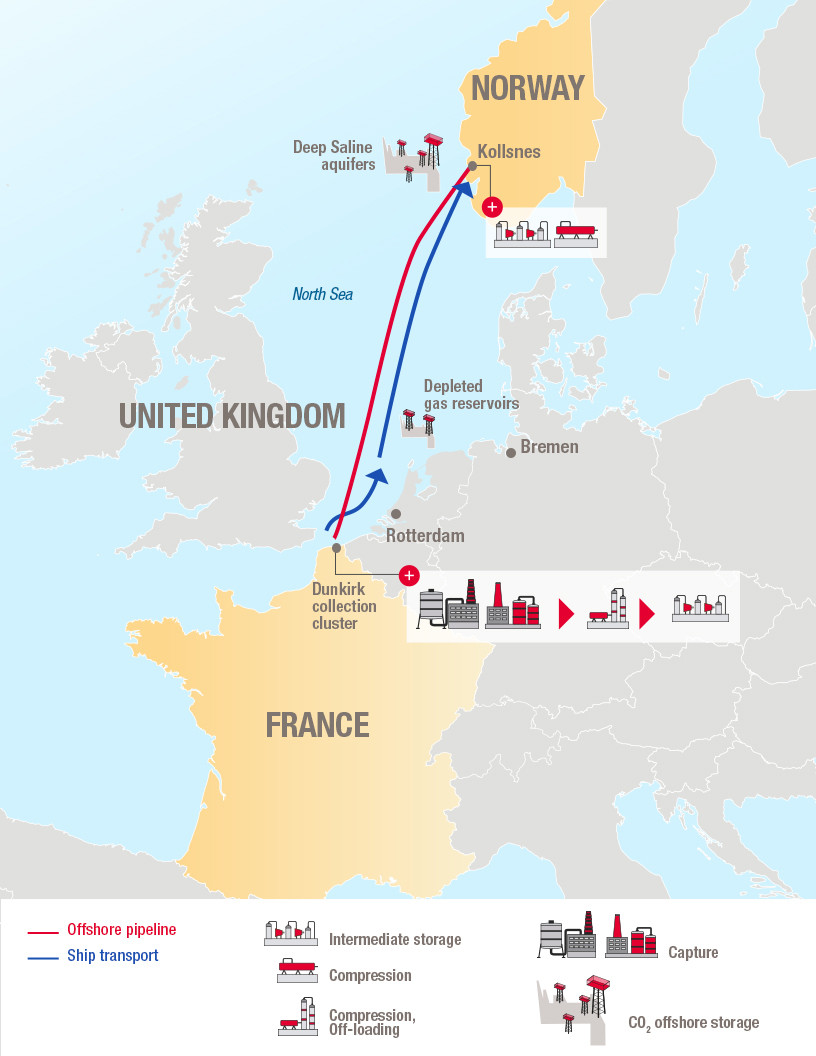

- Design the future European Dunkirk North Sea Cluster, which should be able to capture, pack, transport and store 10 million metric tons of CO2 a year and should be operational by the year 2035. This cluster will be backed up by the packing and transport infrastructures for storing CO2 in the North Sea developed by other projects such as the Northern Lights project(1) that Total is already involved in.

The “3D” project’s ambition is to validate replicable technical solutions and to achieve industrial deployment of Capture & Storage technology around the world. It should play a major role in enabling industries with high energy consumption and CO2 emissions, such as the steel industry, to reduce their emissions. This project is an essential lever for meeting the targets of the Paris Agreement on global warming.

(1) Research project for the capture, storage and reuse du CO2 in Norway

|

CO2 capture and the Carbon Capture & Storage (CCS) process |

IFPEN Contacts

Media Relations: Anne-Laure de Marignan, +33 1 47 52 62 07, presse@ifpen.fr

CO2 Capture and storage Program Manager: Florence Delprat-Jannaud, +33 1 47 52 74 31, florence.delprat-jannaud@ifpen.fr

ArcelorMittal Contacts

Image 7: +33 1 53 70 74 70, arcelormittal@image7.fr

ArcelorMittal in France: Isabelle Chopin, +33 6 15 21 59 25, isabelle.chopin@arcelormittal.com

Total Contact

Media Relations, +33 1 47 44 46 99, presse@total.com l @TotalPress

Axens Contacts

Media Relations, Corinne Garriga, +33 1 47 14 17 14, corinne.garriga@axens.net

Technological Development Director, Stéphane Fédou, +33 1 47 14 67 42, stephane.fedou@axens.net