Supported by its recognized experience in the development of energy production solutions, IFPEN has acquired in-depth expertise in the field of materials for functional use. Today, this expertise is being harnessed to address the emerging challenges of the energy transition, from new battery systems through to the thermal and energy management of processes (compressed air energy storage, process decarbonization, etc.) and new types of powertrain.

Functionalizing a material - i.e., giving it controlled properties as a function of its structure, formulation or chemistry - requires the implementation of approaches combining different physics and different scales.

Considering the growth in computing power available for numerical simulation, over recent years IFPEN’s teams have been implementing a global multi-scale modeling approach, aimed at bridging the gap between the understanding of mechanisms on a small scale (molecular or microstructural) and macroscopic, thermodynamic and mechanical approaches [1-4]. This global approach is hinged around two complementary areas:

- Molecular simulation for an understanding of the physicochemical phenomena or detailed coupling with mechanics.

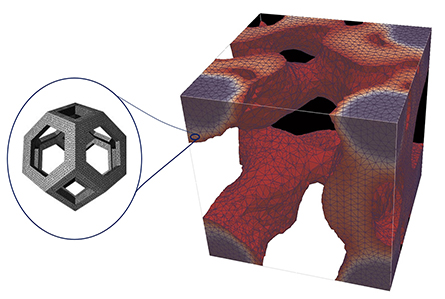

- The simulation of functional usage microstructures making it possible to optimize mass transfer and thermal and mechanical properties within “controlled” architecture materials, for new solutions based on 3D printing.

The approach was initially used to predict, from the molecular scale, the elastic properties of materials presenting several characteristic scales, such as catalyst supports or semi-crystalline polymers (figure 1. a) [1], [2] and [4].

This methodology will also make it possible to improve the prediction of physicochemical properties, such as species solubility in a polymer material and the understanding of interactions with certain solvents (plastic recycling), the understanding of species diffusion in confined media (zeolites, membranes, etc.), or, on a larger scale, to build new structured materials via topological optimization for electric motors, heat exchangers (Figure 1.b) or storage systems [3].

Figure 1. Examples of microstructures and physical problems on different scales.

References:

- B. Belin, M. Yiannourakou, V. Lachet, B. Rousseau (2022). Modeling Method for Semicrystalline Polymers Controlling Aspects of the Morphology at the Molecular Scale for the Study of Mechanical and Physicochemical Properties. The Journal of Physical Chemistry.

>> https://doi.org/10.1021/acs.jpcb.2c04571

- N. Brusselle, V. Le Corre, L. Cangémi. Issue 34 of Science@ifpen - Applied Mechanics.

>> https://www.ifpenergiesnouvelles.com/article/issue-34-scienceifpen-applied-mechanics

- G. O. Agyekum. Shape and topology optimization of Multiphysics Systems. Thesis. Jacques-Louis Lions Laboratory Paris Sorbonne, 2022.

- E. Roguet, K. Akhan, N. Brusselle-Dupend, V. Le Corre, M. Sidhom, L. Cangemi, M. Moreaud, G. Clavier, V. Lachet, B. Rousseau, Investigation of the 3D crystalline network impact on the elastic properties of Semi-Crystalline Polymers from a multi-scale modelling approach. Computational Materials Science 167, 77–84 (2019).

>> https://doi.org/10.1016/j.commatsci.2019.05.006

Scientific contacts: laurent.cangemi@ifpen.fr ; veronique.lachet@ifpen.fr