By combining battery, electric machine, power electronics and mechanical transmission, the electric vehicle is an example of an application that combines a range of constraints for the formulation of technical fluids.

In recent years, there has been renewed interest in the study of the latter for the transport sector.

This concerns both the formulation of products with low environmental impact and the optimisation of blends to meet complex working conditions.

Indeed, in addition to their lubrication and heat transport functions, their compatibility with materials must be ensured, and the presence of electromagnetic fields requires monitoring of their dielectric properties. Finally, all of this must be done without impairing their lifespan, as required by the specifications.

However, the formulation of these fluids still relies heavily on experimental results that are not easily transposable to the new systems under study. In addition, the combination of different stresses increases the complexity of their alteration mechanisms, and therefore the evolution of their properties in service, thereby requiring new experimental and numerical methods to understand their origins and support technological developments where they are present.

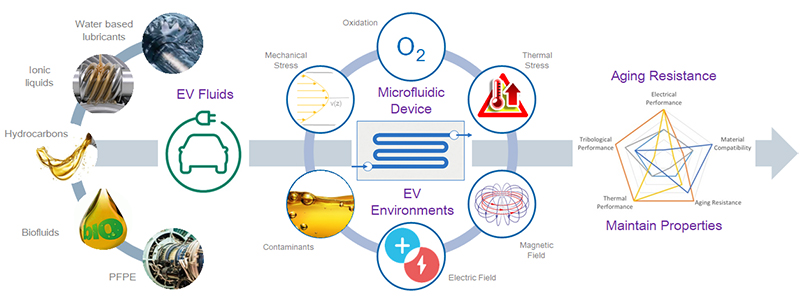

For this reason, IFPEN's teams have launched a research programme to better understand ageing processes in multifunctional environments for the various fluids used in electric vehicles (figure 1). The process is divided into three stages:

- the first aims to assess the response of various fluids to successive stresses, such as measuring the impact of mechanical shear prior to an oxidation process;

- the second is to develop a new experimental device based on microfluidics for coupled characterization of the impact of given stresses (shear, oxidation, electromagnetic field, etc.) on small volumes of fluid;

- the last aims to extend our approaches to the modelling of ageing aspects by combining chemometrics1 and chemical kinetics, based on understanding at the molecular scale, in order to identify relevant chemical descriptors in order to qualify it.

IFPEN has also set up a rheometer equipped with various accessories (magnetorheology, electrorheology, gas purging, temperature control) to carry out in-situ and ex-situ measurements of liquid properties in a controlled environment and under multiple stresses. This equipment is currently being used for the first characterizations of technical fluids in complex environments on behalf of a research consortium initiated at the end of 2022 and led by IFPEN. It brings together carmakers and producers of technical fluids that, in addition to assessing their products, hope to push back the limits of their use, with a view to new applications. In parallel, post-doctoral work is evaluating the use of chemometrics in order to characterize the ageing of these fluids on a laboratory scale [1].

The optimised use of technical fluids in transport is both an economic and an environmental challenge that still raises many research questions, which is why IFPEN is involved in both understanding and deploying the associated resources. To overcome the underlying scientific challenges, this research is also part of a collaborative approach with academic laboratories.

1- Chemometrics is the application of mathematical tools, particularly statistical ones, to obtain maximum information from chemical data.

Bibliographic reference

-

Xu Boyang, Matrat Mickaël, Lacoue-Negre Marion, in preparation.

Scientific contacts: mickael.matrat@ifpen.fr - boyang.xu@ifpen.fr