Compared with conventional stirred reactors, microfluidic systems are of great interest for process intensification, combining low reagent requirements with better performance in terms of mass and heat transfer. In this type of micro-reactor, segmented flows in micro-tubes (also known as Taylor flows) have, for example, been successfully tested at IFPEN to intensify the ethylene oligomerization reaction [1].

Thanks to detailed access to the variables involved, Computational Fluid Dynamics (CFD) is increasingly establishing itself as a reliable, high-performance tool for gaining better understanding and control of the multiphysical phenomena at play in such systems. However, introducing the “reaction” component, in order to have a detailed digital twin capable of simulating a reactive multiphase flow, remains challenging.

A breakthrough to this end emerged from PhD research [2] during which the geometric volume-of-fluid (VOF)1 method was used to “capture” the gas-liquid interface, in the perspective of the direct numerical simulation (DNS) of phenomena. The transport of chemical species was then added to the VOF model to calculate their concentrations. A new discretization strategy for convective and diffusive terms was developed and integrated into the transport equations [3]. This is perfectly compatible with the volume fraction transport equation, avoiding any artificial mass transfer at the interface.

1 available in the OpenFOAM open-source library

The physical source term of mass transfer by concentration between phases could then be implemented in the solver. The complete model was applied to the simulation of Taylor flows in micro-tubes, for the experimental case of the ethylene oligomerization reaction.

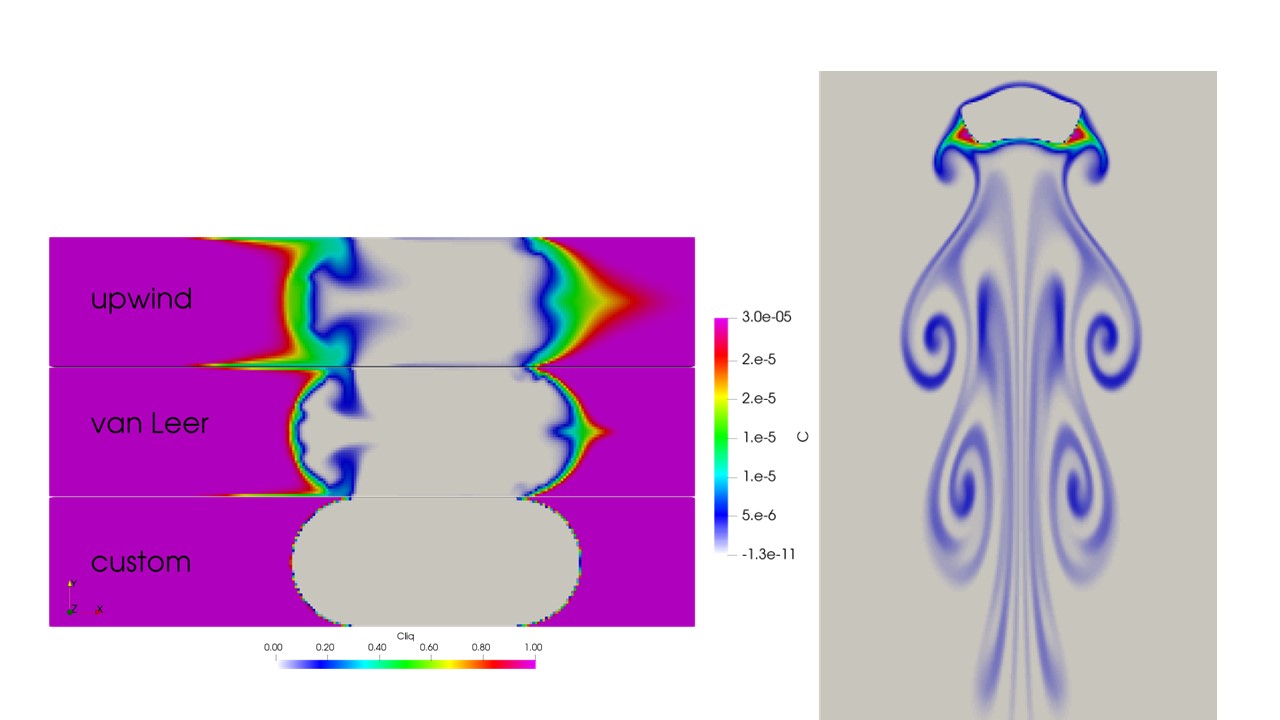

Figure 1 (left) shows the benefit of the new (custom) method in eliminating the error made by other schemes where species transport is not consistent with the volume fraction.

The right-hand side of the same figure shows an example of mass transfer by concentration on a rising bubble in a liquid at rest. At the gas-liquid interface, the regions where mass transfer is greatest are highlighted. The diffusion of the species in the wake of the rising bubble can also be noted.

This new method, which simulates all the equations governing the fluid phenomena involved (DNS), opens up avenues in other similar fields. This is particularly the case for simulating flows in micro-reactors, fixed catalytic beds2 or structured packings, as used in CO2 capture processes.

2 runoff or ascending flows

References :

- M. Kamaleddine, “Transposition de tests de catalyse homogène en micro-réacteur”, thèse de doctorat de l’Institut National Polytechnique de Toulouse (INPT), 2020.

- A. Tourbier, “Numerical simulation of reactive Taylor flows”, thèse de doctorat de l’Institut National Polytechnique de Toulouse (INPT), 2023.

- A. Tourbier, L. Gamet, P. Béard, T. Michel, J. Aubin, H. Jasak, “A consistent methodology to transport a passive scalar with the geometric Volume-of-Fluid method isoAdvector”, Journal of Computational Physics, Volume 513, 2024,

>> DOI : https://doi.org/10.1016/j.jcp.2024.113198

Scientific contact: Lionel Gamet