The Carnot “Industrial Water Treatment” platform addresses the scientific and technical challenges associated with the management of industrial effluents and runoff water, in particular:

The Carnot “Industrial Water Treatment” platform addresses the scientific and technical challenges associated with the management of industrial effluents and runoff water, in particular:

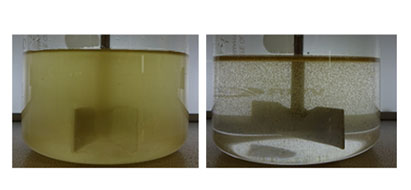

- Emulsion separation (e.g., removal of oil from water)

- The compatibility of water treatment technologies in the presence of additives, such as surfactants or polymers in solution for example

- The pollution remediation of water loaded with particles or new emerging pollutants, such as microparticles, microplastics, dissolved pollutants

- The identification, culture and isolation of microbial players in treatment bioprocesses.

Activity types: Performance of laboratory & pilot tests. Dispersed system modeling. Expertise in complex fluid characterization, physical chemistry of interfaces, cultural and molecular microbiology, and fluid mechanics. Application to industrial cases. R&D services. Multi-partner research projects.

Examples of delivered projects related to industrial water treatment

|

|

|

The platform's activities

- Development of methodological & technological solutions: optimized laboratory solutions validated on a pilot scale.

- Resolution of industrial problems or de-risking of operational risks and proposal of remediation solutions: innovative/disruptive tools for industrial water characterization and treatment.

... based on

- A precise understanding of phenomena (Description of the behavior of liquid/liquid, liquid/gas and liquid/solid interfaces): complementarity between experimental tests and modeling.

- Monitoring of regulations governing ecotoxicity. For example: regulatory toxicity standards and tests for waste water concerning hydrocarbons and additives, BTEX, heavy metals, PAH and emerging pollutants such as microplastics, etc.

|

|

Scientific expertise applied to three priority areas

1. The study of coalescence mechanisms and interfacial and rheological properties of dispersed systems on nano and microscopic scales.

2. Multiphase flow modeling from the micro scale to the macroscopic scale.

3. The understanding of the biological phenomena governing water pollution remediation.

A multidisciplinary team and approach

- Physical chemistry of complex fluids

- Fluid mechanics

- Biotechnologies

- Laboratory analyses

%20et%20drainage%20du%20film%20%C3%A0%20l%E2%80%99interface%20eau-air%20(graphique).png) |

|

Experimental resources on various scales

From the laboratory

- Creation of emulsions and dispersed systems (two-phase) representative of industrial cases (Dispersion rig)

- Separation processes and techniques: gravity, flocculation, coagulation, centrifugation, hydrocyclone, flotation, filtration

- Characterization and study of interfacial (emulsion stability, film drainage, foams, etc.) and rheological (viscoelastic effect, viscoplastic effect, etc.) properties

- Microfluidics cell.

... to pilote

(4 m3/h, 15 bar)

- Flotation skid fitted with modular interiors (injectors, deflectors)

- Liquid-liquid hydrocyclone skid (modular separation chamber)

- Semi-industrial three-phase flow loop (GOwSP, Gas-Oil-water Separation Platform). Liquid flow 10 m3/h:

- Gravity separator: interface monitoring and sampling possibilities

- In-line monitoring of dispersed flows: particle size, concentration, turbidimetry, laser velocimetry measurements, etc.

- Tests in representative conditions

Assessment of the performance of different liquid/liquid, gas/liquid and liquid/solid separation technologies.

Benefiting from advanced operando measurement techniques

Broad pool of analytical equipment enabling the characterization of:

- Fluids: gases, liquids of organic and aqueous origin, colloidal systems

- Study of polymers in solution (molecular mass, hydrolysis rate, concentration, etc.) - Solid materials: deposits, rocks, polymers, steels, etc.

- Spectroscopic methods, gravimetric methods (Raman, FTIR, TGA, etc.)

- Microscopic methods (SEM, EDS)

And a specific analysis:

- of dispersed systems/flows: particle size, turbidimetry, in-line monitoring, monitoring of the mechanical degradation of polymers

- of the interfacial and rheological properties of complex fluids: film drainage, DRA effect, etc.

- of the biological properties: biodegradability evaluation

|

|

Contact: Marie-Hélène Klopffer |

Certification: ISO 9001 (research and innovation activities relating to sustainable systems and technologies in the fields of energy, transport and the environment)