13.10.2025

3 minutes of reading

The oxidation stability of hydrocarbons is a critical property for their use (as aviation fuels, lubricants, etc.), storage and transport. Low stability gives rise to unwanted reactions that can have an adverse effect on the performance of products, reduce their lifespan and, potentially, pose risks in terms of safety. Though robust, conventional experimental methods for characterizing this stability are often costly and time-consuming. Only stringent test conditions, which can sometimes be difficult to fully reproduce, ensure their validity.

To overcome these limitations, a recent study was conducted by IFP Énergies nouvelles in partnership with Lille University, aiming at developing a reliable predictive tool that would avoid the systematic use of laborious tests. The study focused on the use of machine learning, exploiting available experimental data.

A combined experimental/machine learning approach

The approach first required the creation of a database of experimental measurements pertaining to the oxidation stability of various pure hydrocarbons. Machine learning models could then be trained using these reference data.

The models exploit molecular descriptors, i.e. information encoding the chemical structure of compounds, to determine relationships between the nature of the hydrocarbon and its resistance to oxidation. Once calibrated, they become capable of predicting the stability of substances yet to be tested in the laboratory.

Benefits and prospects

There are two benefits associated with this approach. Firstly, it accelerates the substance selection process by rapidly identifying those with high stability, thereby reducing the need for costly experimental campaigns. Secondly, it paves the way for the exploration of a far broader molecular space than that covered by existing data. By offering predictions for compounds that have yet to be discovered, it opens up avenues for obtaining substances with a higher oxidation stability.

The convergence between experimentation and modeling thus delivers a strategic advantage: machine learning continuously guides and enriches research, while laboratory tests focus on the most promising substances.

Conclusion

This study demonstrates that machine learning can play a decisive role in understanding and predicting the oxidation stability of hydrocarbons. This digital tool complements experimental measurements and optimizes the efficiency of research work by guiding scientists toward the most promising avenues. Ultimately, this synergy could contribute to the development of more stable fuels and lubricants, adapted to ever-increasing performance and sustainability requirements.

Reference :

A. Venegas-Reynoso, B. Creton, L. Giarracca-Mehl, M. Lacoue-Negre, C. Ruckebusch, L. Duponchel Oxidation Stability of Hydrocarbons: A Machine-Learning-Based Study, Energy Fuels 2025, 39, 9, 4361–4373

>> DOI : https://doi.org/10.1021/acs.energyfuels.4c04926

Scientific contacts : Marion Lacoue-Negre, Lucia Giarracca-Mehl, Benoît Creton

You may also be interested in

Prediction of fluid oxidation stability via machine learning

IFPEN uses numerous fluids in its fields of innovation for a variety of applications, ranging from renewable energy production to sustainable mobility. Many of the fluids are complex mixtures and the chemistry of their components (hydrocarbons, alcohols, esters, etc.) varies depending on the target application: combustion, cooling, lubrication, electrical insulation, etc.

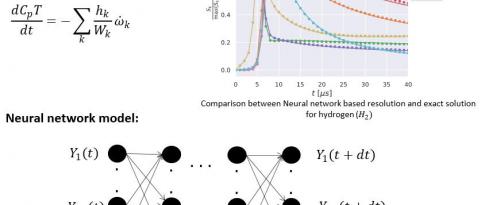

Machine learning accelerates access to high-precision data for chemistry via ab initio molecular dynamics

Acceleration of chemical kinetics calculations through Machine Learning methods

Numerical simulations are now widely employed in the industrial world to help design systems and predict complex phenomena. Reactive flow simulation, for example, is important for numerous applications, such as vehicle and aircraft propulsion and processes in the chemicals industry.