The purification of oil feeds for obtaining clean fuels, as well as the treatment of bio-based feeds that can be incorporated in diesel fuels, rely on the hydrotreatment process and hence on the efficiency of the catalysts used. The latter are the subject of ongoing research to gain a clearer understanding of how they work and improve their performance, in order to reduce the environmental footprint of refining operations. However, current analytical techniques are not capable of characterizing catalysts in their extremely restrictive industrial use conditions (30 to 70 bars, 320 to 380°C).

To overcome this obstacle, an original solution has been found, consisting in miniaturizing a transparent fixed-bed reactor that is then placed inside a Raman spectrometer. This analysis method is conventionally used to characterize catalysts outside unitsa.

In parallel with the challenge of designing a transparent mini-reactor able to withstand high pressures and temperatures, the “measurement” part required a methodological development in order to be able to precisely focus the Raman beam on the chosen target (solid or liquid)(1).

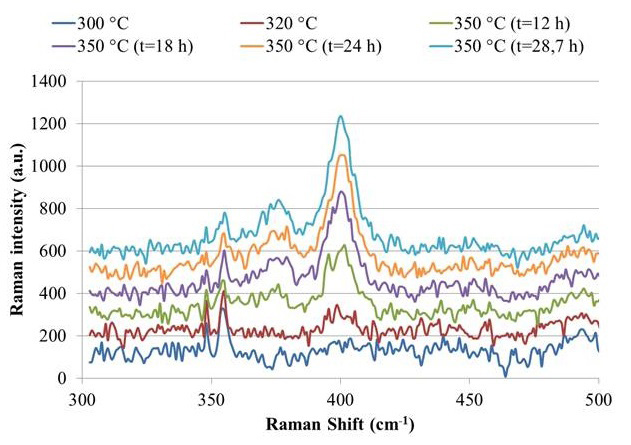

(Raman spectra acquired with a 532 nm laser, power 16mW)

The new system makes it possible — for the first time — to obtain spatial and temporal profiles of solid and liquid phases, during the catalyst activation stepb and during diesel fuel hydrotreatment reactions. For the activation study, for example, it was possible to determine the impact of the liquid feed on the kinetics, as well as the evolution of oxide and sulfide phases (figure).

The tool offers significant potential for studying the various catalytic systems used in refining, in process conditions.

a - At atmospheric pressure and room temperature.

b - Transformation of the oxide phase into active sulfide phase.

(1) M. D. S. Duarte, M. Rolland, C. Sagnard, D. Suire, F. Flacher, O. Delpoux & C. P. Lienemann. A 3 MPa, 350°C transparent fixed bed reactor for operando gas-liquid reaction follow-up. Accepted for publication in Chemical Engineering & Technology.

Scientific contact: marisa.de-sousa-duarte@ifpen.fr