News in brief

Knowledge transfer to new energies

[ DIGITALIZATION AND IA - 2/2 ] One of IFPEN's main areas of research concerns processes and catalysts for the production of bio-based fuels. This is reflected in a large number of experimental projects, the results of which generate knowledge that is then harnessed to develop models. However, this modeling requires the acquisition of large sets of experimental data, which are costly in terms of both time and resources.

Individual page

Philippe BÉARD

Research engineer

Dr, PhD in Fluid Mechanics

Dr, PhD in Fluid Mechanics

PhD in Fluid Mechanics at ISAE-SUPAERO, Toulouse, France in 1994. Research engineer in the Systems Simulation and Modelling Department from 1996 to 2008. Since 2008, research engineer in the Chemical

Individual page

Loïc ROULEAU

Research engineer

Motorization for mobility (>2015) 6 publications, education in mechanical engineer school at Lyon (ECAM) Exploration of porous material synthesis and shaping for catalysis (2003-2014) 34 publications

News in brief

Process Design and Industrial Demonstration, the two sides of the same coin

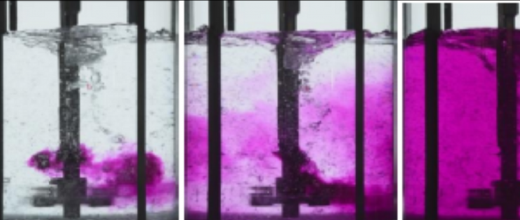

According to the NZE (Net Zero Emission) scenario of the IEAa, the deployment of CCUS (Carbon Capture, Utilization and Storage) needs to accelerate and increase from around 40 Mt of CO2 captured globally in 2022 to 1 Gt in 2030. Among the solutions developed, post-combustion capture using solvents is, so far, considered to be one of the most robust, efficient and appropriate. The DMXTM solution, which addresses the need to have access to effective and economical technologies, is one such option. The fruit of more than 10 years research at IFPEN, this technology, now entering the final development phase, had to be demonstrated in a real industrial setting...

News in brief

Drawing on lessons from the “fossil world” for the benefit of greener processes.

IFPEN is a global leader in the development of fossil feedstocks hydrotreatinga for clean fuel production. Processes from the same family now apply to a broader diversity of feedstocks: plastic and tire pyrolysis oil, in the context of chemical recycling, vegetable oils for biofuel production, etc. For these processes themselves to be eco-efficientb, beyond the targeted environmental benefit, their operating conditions need to be optimized by the use of kinetic or hybrid modelsc, as a function of the feedstocks employed and the specifications sought for the target products...

News in brief

Improving the understanding of enzyme deactivation during lignocellulosic biomass hydrolysis

Driven by the quest for innovative transport technologies, IFPEN has spent many years developing and helping to market new biofuel production processes (Vegan®, Futurol®, BioTfueL®). Among the various process options studied, the bioethanol production chain based on lignocellulosic resources offers numerous advantages...

News in brief

Fox-Prod: effectively combining units for optimized processes

In the energy and chemicals sectors, the conversion of raw materials into finished or semi-finished products is conducted via a succession of processes in dedicated units. Each of these processes comprises input conversion steps and output separation steps. In an industrial context where the focus is on optimizing the use of resources and reducing the environmental footprint, the capacity to redefine and optimize the arrangement of units appeared essential at IFPEN. So its teams developed a tool for the purpose.

News in brief

Foaming processes

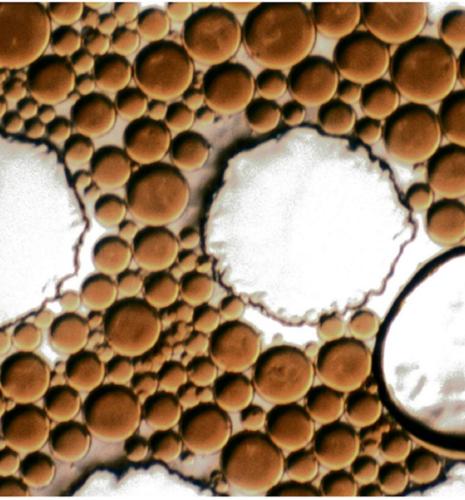

Metal- and ceramic-based solid foams are porous structures that have begun to be used relatively recently in the field of chemical processes although they have been the focus of research at IFPEN for a few years already. Due to their 3D texture, made up of a multitude of juxtaposed spherical cavities (familiar in the field of heterogeneous catalysis), these structures are highly porous (around 70-80%) and have a large specific surface area. On the face of it, this is associated with good external transfer performances...

News in brief

Modeling manufacturing by precipitation - A skill set for the production of battery cathode materials

Building on knowledge acquired relating to alumina precipitation synthesis for heterogeneous catalyst supports, IFPEN’s teams set about working on pCAM synthesis for Li-ion batteries. These materials are indeed also obtained by precipitation in stirred tank reactors, which shares similarities with alumina synthesis (nucleation, growth and agglomeration phenomena). Nevertheless, they come with their own challenges and, consequently, with new research opportunities...

News in brief

Modeling manufacturing by precipitation - A need for catalyst supports

In chemical conversion processes implementing heterogeneous catalysis, the active phase, which accelerates molecular conversions, is often deposited on a porous support. Most of the time, this support has a large internal surface area, making it possible to host a large number of active sites within a small volume. Very often, the porous support is alumina, which needs to have adequate mechanical and thermal resistances and enhance mass and heat transfer. These properties are highly dependent on the texture of the support, which itself stems from its production process...