The diversification of resources (atypical oil feeds or bio-based feeds) is leading to the development of new conversion processesa or to the upgrading of flexibility for existing ones. These developments require precise knowledge of the properties of feeds and their physicochemical status in operating conditions.

However, their nature and composition — usually complex — make these determinations lengthy and difficult.

In addition, during the exploratory phases of R&I projects, these feeds are not necessarily available in sufficiently large quantities to be characterized using conventional tools.

A solution: microfluidicsb. Therefore, by miniaturizing tools to determine thermodynamic properties (phase diagram, density, viscosity), the amount of product used is very limited and results are obtained more quickly(1).

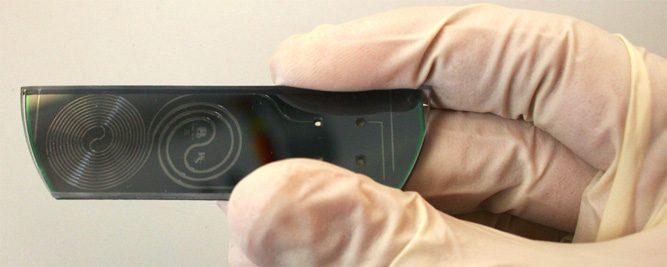

The system we have favored is the silicon/pyrex microchipc (figure). It accepts a broad range of chemical products at P-T (200 bars/400°C) conditions typical of conversion processes. Compared with conventional systems, this method has made it possible to determine the supercritical points of “real feed/hydrogen/solvent” mixtures with acquisition times that are reduced five-fold(2), a lower cost and sufficient precision to supply data both for experiments on pilot units and process simulationd.

After having developed a microfluidics test bench for the acquisition of thermo-dynamic data, research conducted in collaboration with the ICMCBe aims to explore the potential of this technology for the assessment of homogeneous catalysts and the separation of reaction products.

a - Processes aimed at breaking down large hydrocarbon molecules in order to obtain lighter products.

b - Science of manipulating minute volumes of fluids, with at least one characteristic dimension in the region of a micrometer.

c - A silicon wafer engraved with channels and covered with a pyrex plate.

d - This research was awarded the International Society for Advancement of Supercritical Fluids’ 2016 thesis prize.

e - Institut de chimie de la matière condensée de Bordeaux.

(1) B. Pinho, S. Girardon, F. Bazer-Bachi, G. Bergeot, S. Marre, C. Aymonier, The Journal of Supercritical Fluids 2015.

DOI: 10.1016/j.supflu.2015.04.016

(2) B. Pinho, S. Girardon, F. Bazer-Bachi, G. Bergeot, S. Marre, C. Aymonier, Lab on a chip 2014, 14 (19), 3843–3849.

DOI: 10.1039/c4lc00505h.

Scientific contact: ghislain.bergeot@ifpen.fr