24.10.2022

3 minutes of reading

In an effort to fully embrace all the challenges facing applied thermodynamics in the coming years, a group of experts affiliated with the European Federation of Chemical Engineers, and coordinated by an IFPEN researcher , has published a summary document “A View on the Future of Applied Thermodynamics”.

> Download the study (PDF - 1,8 Mo)

Applied thermodynamics is used to describe the evolution of a system over time, by considering how it exchanges matter and energy with the environment. Applications range from chemistry to mechanics, physics and energy.

Overview of the highlights of this summary:

The escalating use of new resources for more and more new products

Industries are transforming and placing a strong focus on the circular economy. In effect, waste represents a huge potential for recycling. For example, plastics, lithium from used batteries, plant debris and catalysts could be recycled over and over again, provided an energy source is available. However, to do so, suitable processes must be designed, and the tools offered by thermodynamics can be used to understand and optimize these processes.

Another aspect of the changes in the industry is the proliferation of new and increasingly diversified products to address a variety of needs in the health, food, chemical and other sectors. These products often use complex polyfunctional molecules, which are found for example in biobased materials, surfactants, polymers or electrolytes. Here too, applied thermodynamics will help to improve our understanding of the complex chemistry of these molecules.

New processes and improved analysis of their energy efficiency

In order to develop a new process or a new product, thermodynamic studies are essential to evaluate the feasibility and relevance on solid foundations. For example, life cycle assessments (LCA) can use the concept of exergy, which describes the minimum energy cost associated with a process. Converting biomass into bioethanol is a good example of a process that can be assessed using this concept.

Furthermore, energy and chemical transformation processes can benefit from the insight of experts in thermodynamics:

• Today, the hydrogen economy is considered as a possible alternative to the current energy model that is based on using fossil resources. However, this new paradigm still needs to be proven: the energy cost associated with manufacturing hydrogen is often extremely high. Applied thermodynamics provides the means to assess the conditions under which this energy carrier may be of interest, compared with alternative chemical energy carriers such as methanol or ammonia.

• Processes that aim to use CO2 as a carbon source must also be investigated through precise thermochemical studies. In effect, to transform this molecule, energy is required and the efficiency of these processes compared to alternatives must be rigorously established.

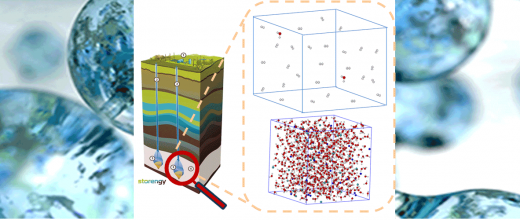

• Energy storage scenarios consist of converting energy into thermal, mechanical, electrochemical or chemical form. Only a thermodynamic analysis can assess how relevant the various solutions actually are, with the conversion of electricity into hydrogen being one of the possible solutions.

The importance of models and data

Thermodynamic concepts are usually incorporated by the industry through software that uses more or less predictive models. These models must be parametrized and validated, which implies proper expertise: the parameters must be adjusted in accordance with the required property, the mixture being considered, the operational conditions and above all, the data available for validation. These data, which are essential to build and assess the models, are not always available or are of insufficient quality to be easily used. It is becoming increasingly important to evaluate the quality of existing data and to carry out new measurements as the diversity of the systems under study increases: predictive methods reach their limits when the operating conditions fall outside the range of known conditions. Furthermore, providing such data in a practical and standardized form also remains a daunting challenge. To solve these diverse data issues, one possible way out is to use artificial intelligence tools.

Thermodynamics, a route to excellence for future generations

Considering the errors that can reduce or even nullify the efficiency of processes, thermodynamics is essential for calculations and development in chemical engineering. Unfortunately, a downward trend in expertise is apparent in a large number of companies.

To overcome this skills deficit, studies in chemistry and thermodynamics need to be put back on the agenda in secondary and higher education. Chemistry students need to be taught more about how to work with phase equilibria and the main models. Similarly, PhD programs must be encouraged to train the specialists that the industry actually needs. Finally, high-quality lifelong education and training must enable these experts to keep up to date and to maintain a watchful eye throughout their professional careers in order to be able to tackle the constantly increasing challenges of thermodynamics in industrial applications.

Did you know?

IFPEN has set up the Elether research consortium with seven industrialists to study electrolyte thermodynamics. This consortium is supported by the Elether chair hosted by the IFP School’s “Processes for Energy and Chemicals” center.

Through the use of deep learning data, it was possible to speed up the flash calculation of phase equilibrium in a mixture.

Chemoinformatics can be used to predict the behavior of polymers in contact with fluids.

Scientific contact : Jean-Charles de Hemptinne