News in brief

Lewis acid zeolite catalysts for the conversion of sugars into chemical molecules of interest

Biomass conversion using chemical products and intermediates is increasingly being adopted to reduce the carbon footprint of this industry. Among biomass-based resources, sugars are extremely attractive since they contain a lot of functional groups enabling their conversion into products of interest (alcohols, acids, etc.). This conversion requires the use of catalysts, including heterogeneous catalysts based on zeolites with Lewis acidity , which have demonstrated strong potential, due to the presence of a tetravalent metal in the lattice position.

Individual page

Philippe BÉARD

Research engineer

Dr, PhD in Fluid Mechanics

Dr, PhD in Fluid Mechanics

PhD in Fluid Mechanics at ISAE-SUPAERO, Toulouse, France in 1994. Research engineer in the Systems Simulation and Modelling Department from 1996 to 2008. Since 2008, research engineer in the Chemical

News in brief

IFPEN and the B-BEST PEPR

IFPEN and INRAE are leading the B-BEST PEPR*, the research component supporting the French national acceleration strategy relating to “Bio-based products and industrial biotech - sustainable fuels”

Individual page

Etienne GIRARD

Research scientist in Catalysis / R&I Project manager

Following an engineering degree obtained from Chimie ParisTech (2008), I completed my research career with an academic thesis at the University of Toulouse (obtained in 2012), on the design and

Individual page

Francesco PATACCHINI

Research engineer in scientific computing

Francesco Patacchini is a research engineer in scientific computing and, more generally, in applied mathematics. He obtained his PhD at Imperial College London in 2017 under the supervision of Prof

Individual page

Charles-Philippe LIENEMANN

Charles-Philippe Lienemann - Scientific Advisor at the Physics and Analysis Division

Charles-Philippe Lienemann graduated at the University of Geneva (Switzerland) in 1993. He then joined University of Lausanne (Switzerland) within the group of D. Perret and Prof. J-C. Bünzli for his

Individual page

Nicolas FERRANDO

Project manager / Research Engineer

Nicolas Ferrando is graduated of Ecole Nationale Supérieure des Ingénieurs en Génie Chimique (Toulouse) with a Chemical Engineering master degree, followed by a PhD in Chemistry from Université Paris

Issues and Foresight

Bio-based chemistry

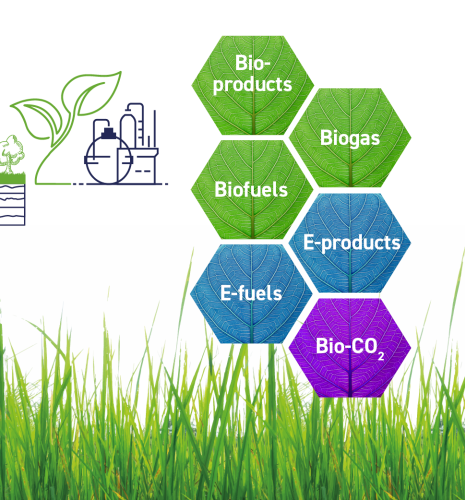

Bio-based chemistry is chemistry in which fossil resources are partially or completely replaced by resources derived from biomass. In particular, it helps limit reliance on fossil resources for the production of certain types of products and reduces the environmental footprint of these products.

Innovation and Industry

Bio-based chemistry

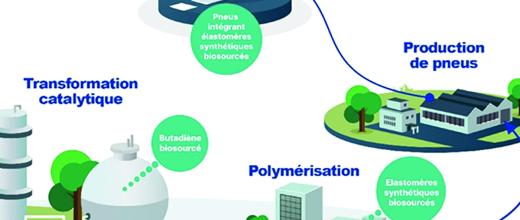

BIO-BASED CHEMISTRY OVERVIEW AND CHALLENGES The development of base material production processes for the chemicals sector using biomass addresses a triple objective: use renewable raw materials in order to reduce greenhouse gas (GHG) emissions and tackle climate change, contribute to the development of a circular economy, reduce the chemical sector's

Innovation and Industry

Renewable energies

The energy transition and tackling climate change depend on the development of new renewable resources. IFPEN proposes processes for the production of fuels, bases for the chemicals sector and gas from biomass. IFPEN also uses its expertise acquired in the field of oil and gas to offer solutions for the