Chemical Looping Combustion (CLC) is an airless combustion technology using oxygen carrier materials (OCM), which circulate between an oxidation and a

reduction reaction zone. Separation into two zones enables nitrogen-free combustion, generating an effluent composed solely of CO2 and steam, which

are easy to separate.

Most research in the field of CLC has been conducted on small-scale pilots (<150 kW). This was the case for the development of reaction zones at IFPEN, with models on different scales and a 10 kWtha pilot leading to the characterization of the combustion kinetics on the basis of feed and OCM(1).

However, to prepare for industrial extrapolation(2), demonstration on a larger scale (> MW) is necessary, in representative hydrodynamics and reaction

conditions whereby the main technological challenges can be addressed:

• extrapolation and optimization of reaction zones and energy loss minimization;

• controlled, stable circulation of OCM between reactors;

• performance of the various OCM over a very large number of redox cycles;

• control of tightness between the two reaction zones to prevent leaks.

different solid and gas flow conditions.

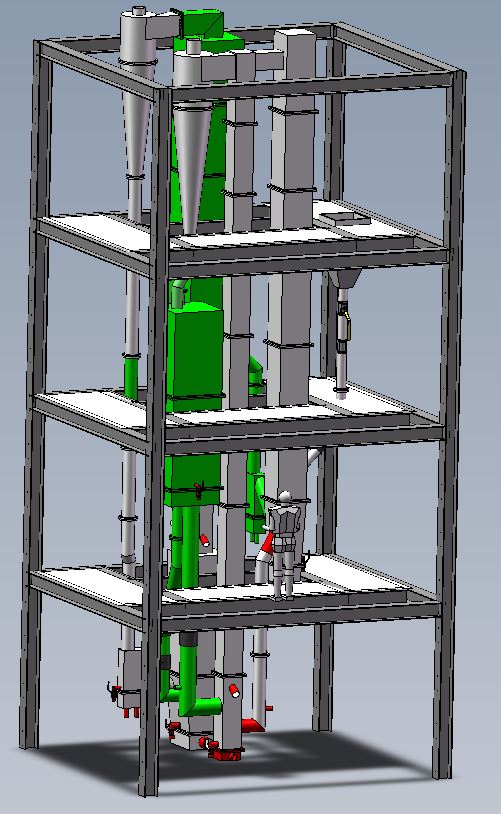

The Sino-European collaborative project CHEERSb aims to construct and operate a 3 MW demonstrator, based on an innovative conceptc aimed at using oil

industry waste as feeds. Recently, a cold flow model (figure), with a size equivalent to a 1.5 MWth unit, of the entire reaction section was constructed and operated in China to study:

• the hydrodynamics of each section,

• the efficiency of separation between the unburned components of the solid feed,

• and the OCM, and control of solid circulation.

a - Thermal kW

b - Chinese European Emission Reduction Solutions

c - Developed with Total

(1) A. Lambert, A. Tilland, W. Pelletant, S. Bertholin, F. Moreau, I. Clémençon, M. Yazdanpanah, Fuel 216 (2018): 71-82.

DOI: 10.1016/j.fuel.2017.11.115

(2) T. Gauthier, M Yazdanpanah, A. Forret, B. Amblard, A. Lambert, S. Bertholin, Powder Technology 316 (2017): 3-17.

DOI: 10.1016/j.powtec.2017.01

Scientific contact: sina.tebianian@ifpen.fr