Electrification of the vehicle powertrain is one of the keys to sustainable mobility and hybridization with internal combustion engines is becoming increasingly common. In this context, the “48-volt” mild hybrid system is a low-cost, flexible and easy-to-integrate option, with reduced safety constraints and outstanding performances.

However, 48-volts systems tend to target relatively low power levels, providing only assisting torque for propulsion and limited braking energy recovery. These limitations are the result of the low voltage used for both the source (battery) and the load (electric motor).

An innovative approach was conducted by a team of lecturers-researchers and students from the Powertrain Engineering program at IFP School, as part of a final year project: an optimization approach combining an enhanced powertrain structure and a dynamic energy management strategy. This combination allows to overcome the initial limitations and operate with higher electric powers, thereby enabling all-electric propulsion in urban environment for a light hybrid vehicle[1].

Supplying high levels of power at low voltage imposes severe constraints on the battery and the electric motor: thermal stress and premature ageing, high currents and considerable losses. The in-depth analysis of these constraints allowed to separate their dynamics and to distribute them to the various components of the onboard energy system.

Regarding the source, it was decided to combine a power source (supercapacitor) to meet the requirements of high dynamics and an energy source (48-V battery) to meet the requirements of low dynamics. As for the load, it is provided by two judiciously scaled and positioned electric motors (figure 1).

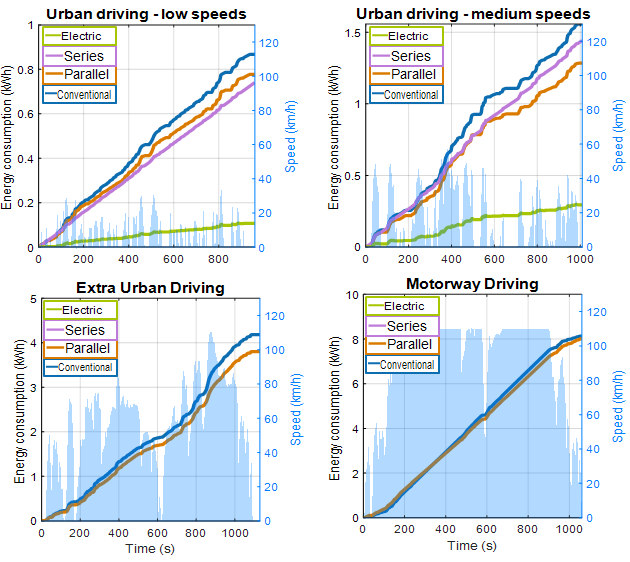

This configuration has been completed by the implementation of a dynamic energy management strategy during the driving cycle (figure 2). Depending on the required performances, the consumption reduction objectives and the battery state of charge, the functional architecture of the powertrain self-adapts in real time. The energy management strategy can thus use the all-electric mode (MG1+MG2), the series hybrid mode (MG2), the parallel hybrid mode (ICE+MG2) or the conventional IC mode (ICE).

Click on the picture to enlarge

MG: Motor/Generator

ICE: Internal Combustion Engine

CVT: Continuously variable transmission

CL: Clutch

The proposed propulsion architecture and energy management strategy offer very high operating flexibility with the potential to reduce fuel consumption and pollutant emissions at low cost, with simplified integration.

Based on these results, a new project is under way to investigate the possibility of using the 48-volts system for very high power levels, suitable for all-electric urban vehicles.

[1] O. El Ganaoui-Mourlan, E. Miliani, D. Carlos Da Silva, M. Couillandeau et al., Design of a Flexible Hybrid Powertrain Using a 48 V-Battery and a Supercapacitor for Ultra-Light Urban Vehicles, SAE Technical Paper 2020-01-0445, 2020

>> DOI: 10.4271/2020-01-0445

Scientific contact: el-hadj.miliani@ifpen.fr

![[Study] Vehicle electrification: an effective solution aimed at reducing the environmental footprint associated with transport](/sites/ifpen.fr/files/styles/crop_fil_actu_paysage/public/inline-images/NEWSROOM/BANDEAUX%20THEMATIQUES/Mobilit%C3%A9%20durable/MobiliteDurable.png?h=ce972e13&itok=qBQyJ2b-)