De nombreux procédés catalytiques utilisent les réacteurs à lits fixes arrosés car ils présentent de nombreux avantages. Simples d’utilisation, ils ont de bonnes performances en termes de mise en contact des gaz, liquides et solides. Néanmoins des phénomènes complexes y sont à l’œuvre et pour les comprendre il est nécessaire de recourir à la mécanique des fluides numérique. Un travail de thèse a permis d’obtenir des résultats en accord avec les observations.

An apparently simply design that hides considerable complexity

Due to their relatively practical design and their ease of use, fixed trickle bed reactors are considered to be the best gas-liquid-solid contact technology for a broad range of catalytic processes. Although simple to use, these reactors combine several complex phenomena.

In order to gain a better understanding of these phenomena, several literature reviews have focused on the characterization of reactors of this type, but few of them have tackled matter transfer at the interfaces. Moreover, significant disparities have been observed in the estimation of parameters of interest: feed loss, liquid saturation, wetting rate as well as gas-liquid and liquid-solid matter transfers.

Realistic estimation of parameters of interest

With a view to gaining a better understanding of local phenomena, a PhD thesis [1] using computational fluid dynamics (CFD) studied the complex coupling between hydrodynamics and matter transfer in realistic industrial operating conditions. To do so, predictive gas-liquid-solid transfer simulations were conducted. Hydrodynamic predictions concerning feed loss and liquid saturation were validated with respect to reliable models in the literature (Ergun’s equation, [2]). Similarly, the grain wetting rate was compared to a previously established correlation [3], also taking into account the effects of gas flow and grain shape.

A broad range of case studies, catalyst geometries and grain shapes

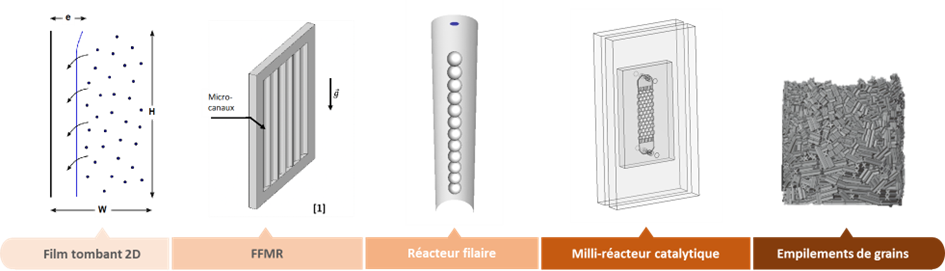

For CFD modeling, a strategy involving the gradual complexification of case studies was adopted (Figure 1), from the case of a two-dimensional, semi-infinite falling film to that of a three-phase reactive medium, with very good agreement concerning hydrodynamics and matter transfer flows.

The CFD model was evaluated to study the effect of the geometry of the solid catalyst in three configurations: (i) a string reactor, (ii) a structured millireactor, (iii) three stacks of fixed trickle beds comprising spheres, trilobes and quadrilobes. In these case studies, an acceleration of external transfers was revealed and quantified for tortuous flows, due to the convective contribution of the solute limiting the reaction. The study of transfer in fixed trickle bed reactors, for various grain shapes, demonstrated an improvement in transfer coefficients for particles with a high surface/volume ratio.

Lastly, the effects of gas flow and grain shape on partial wetting of the solid surfaces were simulated in real process conditions, making it possible to broaden the scope of application of the correlation already stated [3].

A better understanding of local phenomena

Using computational fluid dynamics, this research has made it possible to study hydrodynamics and gas-liquid-solid matter transfer on a local scale, and improve both the understanding and determination of the parameters of interest. As a result, correlations are proposed to (i) estimate the wetting rate in grain stacks and (ii) correct the series resistance model, widely used in industry to estimate the global transfer coefficient.

References:

[1] Bouras, Hanane (2021) Etude expérimentale et numérique des transferts de matière externes dans différents réacteurs catalytiques triphasiques en régime ruisselant. En ligne : www.theses.fr/2021LYSE1021

[2] Boyer, C.; Volpi, C.; Ferschneider, G. (2007) Hydrodynamics of trickle bed reactors at high pressure: Two-phase flow model for pressure drop and liquid holdup, formulation and experimental validation. In : Chemical Engineering Science, vol. 62, n° 24, p. 7026–7032. DOI:https://doi.org/10.1016/j.ces.2007.08.036.

[3] Julcour-Lebigue, Carine; Augier, Frédéric; Maffre, Harold; Wilhelm, Anne-Marie; Delmas, Henri (2009) Measurements and Modeling of Wetting Efficiency in Trickle-Bed Reactors: Liquid Viscosity and Bed Packing Effects. In : Industrial & Engineering Chemistry Research, vol. 48, n° 14, p. 6811–6819. DOI: https://doi.org/10.1021/ie9002443.

Scientific contact : hanane.bouras@ifpen.fr

You may also be interested in

HTE in a milli-fixed bed reactor boosts the development of slurry catalysts

THÈSE DE CHARLES BONNIN

Mieux comprendre les phénomènes de diffusion au cœur des catalyseurs

Characterizing catalysts for Fischer-Tropsch: a question of SWING

Fischer-Tropsch synthesis is a catalytic process to produce hydrocarbons from a syngas, which could come from biomass.