Individual page

Philippe BÉARD

Research engineer

Dr, PhD in Fluid Mechanics

Dr, PhD in Fluid Mechanics

PhD in Fluid Mechanics at ISAE-SUPAERO, Toulouse, France in 1994. Research engineer in the Systems Simulation and Modelling Department from 1996 to 2008. Since 2008, research engineer in the Chemical

Individual page

Loïc ROULEAU

Research engineer

Motorization for mobility (>2015) 6 publications, education in mechanical engineer school at Lyon (ECAM) Exploration of porous material synthesis and shaping for catalysis (2003-2014) 34 publications

Individual page

Minh Tuan NGUYEN

PhD. Research engineer

Minh Tuan Nguyen completed an Engineer degree from Da-Nang University of Technology (Vietnam) in 2012, and a Master of Science degree from Ecole Nationale Supérieure de Chimie de Lille (ENSCL) and IFP

Individual page

Antoine FECANT

Head of Department

Antoine Fécant holds an engineering degree from the Ecole Normale Supérieure de Chimie de Lille (2004) and a DEA (Master degree) from the University of Lille I the same year. He then obtained a PhD

Individual page

Maira ALVES FORTUNATO

Researcher in Complex Fluids / Ph.D. in Chemistry

_ Maira completed her Ph.D. thesis at the Institute for Research on Catalysis and the Environment of the University Claude Bernard Lyon 1 (CNRS) and Saint-Gobain Provence Research on the catalytic

Individual page

Charles-Philippe LIENEMANN

Charles-Philippe Lienemann - Scientific Advisor at the Physics and Analysis Division

Charles-Philippe Lienemann graduated at the University of Geneva (Switzerland) in 1993. He then joined University of Lausanne (Switzerland) within the group of D. Perret and Prof. J-C. Bünzli for his

Innovation and Industry

Petrochemicals: Our strengths

Petrochemicals Our strengths Recognized expertise in the field of catalysis, separation and processes. Integration in a public-private partnership ecosystem with the collaborative platform Axel’One. A proven transfer model in which IFPEN’s innovations are taken to market by its industrial partners, who handle industrial scale-up and marketing. Its subsidiary Axens is

Innovation and Industry

Petrochemicals: Our solutions

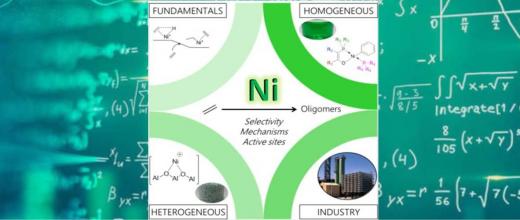

IFPEN’s research focuses on the development of olefin and aromatic production catalysts and processes with a view to improving the performance of existing technologies, increasing the purity of the products obtained and consuming less energy.

Innovation and Industry

Petrochemicals

PETROCHEMICALS OVERVIEW AND CHALLENGES Petrochemical processes are designed to convert oil and natural gas cuts into base chemicals (the major intermediates) for the chemicals industry, such as olefins and aromatics. These compounds are subsequently used to manufacture chemicals used in a number of fields: plastics processing, pharmacy, agriculture, cosmetics, electronics

Innovation and Industry

Responsible oil and gas

Against the backdrop of the accelerating energy transition, the oil industry and related sectors need to continue to meet sustained demand, while significantly reducing their environmental footprint and energy consumption. IFPEN develops eco-efficient and flexible processes for the production of fuel and chemical intermediates meeting the strictest standards. To make

![IFP Energies Nouvelles' scientific meetings : Solid Liquid Interfaces – Challenging Molecular Aspects for Industrial Applications [SLIMAIA]](https://www.ifpenergiesnouvelles.com/sites/ifpen.fr/files/styles/crop_fil_actu_paysage/public/inline-images/NEWSROOM/BandeauNewsroom_RA2016.png?h=4d810dc0&itok=Azwpeoo7)