Heterogeneous catalysts are materials that make chemically possible and economically viable countless industrial processes in the service of energy-related and environmental problems, such as fuel production and air quality (vehicle emissions, building interiors). Their implementation involves two major scientific challenges:

1) the identification of the chemical, structural and morphological properties of an optimal catalyst1,

2) the evolution of these properties over the catalyst’s life-cycle (synthesis, preparation, use, recycling).

In order to make progress in overcoming these challenges, the characterization of the material in all its successive states, including during operation, is a key step, but it is also a process that is experimentally demanding.

With this in mind, “in situ2 and/or operando3“ methodological approaches make it possible to study the evolution of a material and its fluid environment in physicochemical conditions representative of a manufacturing step or a catalytic reactor. They therefore offer a remarkable advantage over so-called ex situ approaches, which are limited to the final, out-of-context observation of all or part of a complex transformation mechanism.

Within the framework of collaborative research work, IFPEN has contributed to the development and implementation of such approaches, illustrated by the three following examples:

With a view to controlling the synthesis of the catalyst

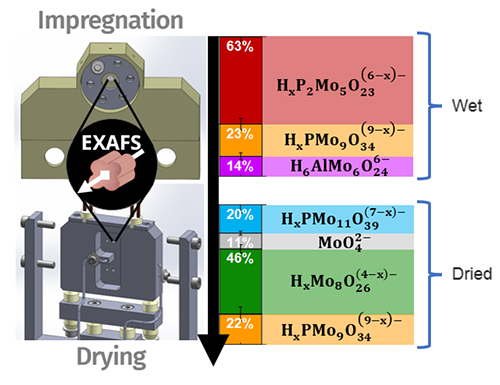

Hyperspectral synchrotron X-ray absorption imaging in impregnation/maturation/drying conditions was developed on the ROCK beamline of the SOLEIL Synchrotron at Gif-sur-Yvette (figure 1). This made it possible to monitor:

- the mobility and chemical speciation4 of the different catalytic species (in this case molybdic) of an impregnation solution in mesoporous alumina extrudates (the support),

- the evolution of these species during drying,

- all with relevant time and space resolution vis-à-vis observed phenomena (to the minute and ten or so µm respectively).

This has enabled a better understanding of the heterogeneity of distribution and the nature of active phase precursors due to interaction with the support during these synthesis steps [1].

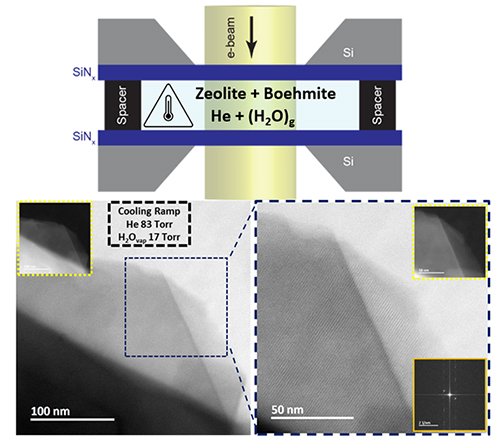

Another example5, the implementation of hydrothermal conditions in environmental cell TEM6, made it possible to investigate the dealumination, via hydrolysis, of faujasite zeolites for the manufacture of acid catalysts [2]. This development was carried out alongside a study using the same system to dehydrate boehmite, by calcination, for the production of transition aluminas. It was thus possible to observe both these phenomena simultaneously for the first time by TEM (figure 2).

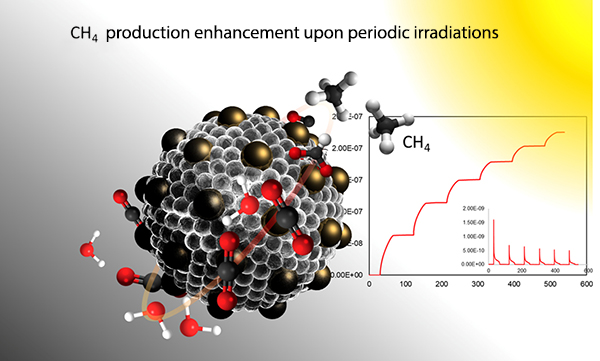

To study a reaction mechanism

Fourier Transform Infrared Spectroscopy (FTIR) was used to study the photoreduction of CO2 in the presence of water vapor, on a co-catalyst made up of platinum nanoparticles supported on titanium dioxide (figure 3). An operando methodology7 was used to reveal the impact of carbon impurities on the measured activity and hence the need to control the initial surface state of the photocatalyst. Day/night cycle operando IR measurements also provided an insight into how to improve photocatalyst efficiency, as well as information concerning the reaction mechanisms taking place on the surface of these materials [2]. For example, acetate intermediates were identified by subsequent isotopic measurements, which revealed the presence of Carbon-Carbon coupling reactions.

In all of this research, it became clear that the processing of big and/or noisy data is essential. The development of chemometric and data extraction methods for X-ray absorption and infrared spectroscopies, as well as denoising approaches for electron microscopy, now represent crucial development avenues to be explored alongside instrumentation.

1- In terms of properties: activity, selectivity, stability

2- In relevant local conditions, without sampling

3- In reaction conditions, with monitoring of evolutions and products

4- Identification and quantification of the different possible species of an element in a given environment

5- Research conducted with the Strasbourg Institute of Materials Physics and Chemistry

6- Transmission Electron Microscopy

7- Developed in collaboration with the Laboratoire de Catalyse et Spectrochimie de Caen (LCS)

References:

- B. Barata, C. Legens, E. Devers, O. Delpoux, L. Barthe, O. Roudenko, V. Briois, Chemical Speciation by Quick-XAS and Raman Spectroscopy: Validation of Two Cells for in situ Time-Resolved Monitoring of the Impregnation and Drying of CoMoP/Al2O3 Catalysts, ChemCatChem, Volume15, Issue7, 2023

>> https://doi.org/10.1002/cctc.202201440

- J. Dankar, V. Rouchon, C. Pagis, M. Rivallan, M. El-Roz, Exploring the effect of the reaction conditions on the mechanism of the photocatalytic reduction of CO2 in the vapor phase over Pt/TiO2: an operando FTIR study, Inorg. Chem. Front., 2023,10, 7155-7166

>> https://doi.org/10.1039/D3QI01758C

- V. Girelli Consolaro, W. Baaziz, V. Rouchon, O. Ersen, Insight into the Mesopore Formation in Zeolites by Operando and 3D Electron Microscopy, Microscopy and Microanalysis, Volume 27, Issue S2, 1 November 2021, Pages 87–88

>> https://doi.org/10.1017/S143192762101343X

Scientific contacts: christele.legens@ifpen.fr, mickael.rivallan@ifpen.fr and virgile.rouchon@ifpen.fr

You may also be interested in

Photocatalysis, a lighted pathway for CO2 conversion

Although the climate crisis makes the reduction of CO2 emissions a matter of urgency, some industries will have difficulty in avoiding them, such as cement plants (where the core process is currently based on the calcination of CaCO3) or refineries, which are currently highly energy-intensive. Hence the huge potential interest in procedures that could capture the CO2 released directly from the plant (...) then recover it at a fraction of the energy cost...

Operando spectroscopy in full transparency

THESIS OF MARISA DE SOUSA DUARTE