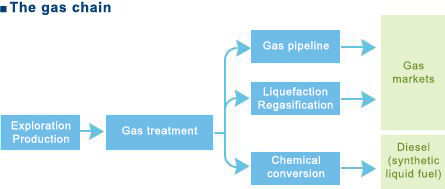

Like oil, natural gas is a fossil energy that is also the result of the decomposition of organic materials on the ocean bed. One of the specific characteristics of the gas chain concerns transport, an essential link and one that, due to the high costs involved, has a major impact on the development of natural gas.

What is natural gas made of?

The main constituent element of natural gas is methane. Methane is a hydrocarbon comprising one carbon atom and four hydrogen atoms. In order to be used, natural gas may need to be sweetened (removal of most of the acids, carbon dioxide and hydrogen sulfide) and undergo stripping (removal of heavy gas fractions). Whatever the case, it needs to be dehydrated. The aim of all these operations is to eliminate the impurities present with the gas as it leaves the well.

Intrinsic properties of natural gas

These properties are primarily linked to its high energy efficiency and environmental advantages: its combustion emits no dust particles, little sulfur dioxide (SO2), little nitrogen dioxide (NO2) and less carbon dioxide (CO2) than other fossil energies. Moreover, the volume it occupies can be reduced by liquefying it. Primarily made up of methane, it is colorless and odorless, but it is “odorized” to make it detectable.

How is natural gas extracted ?

Oil’s twin energy, its extraction follows similar steps: surface observation for indications of its presence, underground evaluation, seismic evaluation and drilling. Moreover, natural gas is frequently found in the same places as oil and the reverse is also true. Due to transport-related constraints and the absence of a captive market, the most important question, prior to any decision to go ahead and develop a new gas field, relates to the availability of an outlet for the quantities that will be produced.

Extraction, production and treatment, 3 key steps

Like oil, natural gas can be extracted from the land or sea. Before being delivered to the consumer, gas extracted from the reservoir rock is piped to treatment plants. It is then processed in a purification system to eliminate byproducts (nitrogen, carbon dioxide, helium, etc) - extracted with the gas but non-combustible, reducing the calorific value of the gas -, as well as corrosive compounds (sulfur), which damage the transport infrastructures. Other usable compounds, such as natural gas liquids (ethane, propane, butane, etc.) and condensates, are also extracted and exploited in the petrochemicals and refining industries.

More than 65% of the world’s proven natural gas reserves are concentrated in Russia and the Middle East (Iran, Qatar, etc.). Offshore reserves represent around 1/3 of global gas reserves.

How is natural gas transported?

Due to the low energy density of natural gas, there are a number of associated transport constraints that have an impact on the development of its commercial trade.

The substantial transport costs involved mean that distance is a major factor when it comes to the marketing of gas: 2/3 of global production is marketed in producing countries with only the remaining third traded internationally. The share of international trade in global production is increasing due to the fact that production zones are gradually getting further away from consumption centers.

Transport via gas pipeline

This is the most widely employed option. It is four or five times more expensive than transporting oil via pipeline. Natural gas needs to be compressed every 120 to 150 km by compressor stations. This is because it is the difference in pressure that causes the gas to travel, at speeds of between 15 and 20 km/hour.

Transport via LNG tanker

This option is used when long distances are involved or when there are difficulties associated with the geopolitical or geographic conditions of the countries through which the gas has to travel. By offering ever more flexibility and arbitrage opportunities on the international markets, transport via LNG tanker is booming and playing a growing role in gas trade. The natural gas is transported in liquid form, hence the terminology LNG (liquefied natural gas). Once in the purchasing country, it is converted back to gas.

Today, more than two thirds of gas traded is transported via gas pipelines - over land or under the sea -, with the remainder transported by LNG tanker.

The importance of storage

Storage is necessary in order to be able to ensure consumption and gas resources can be adjusted so that consumers have access to energy at all times. Natural gas is generally stored in depleted gas and oil fields, aquifers or salt caverns. In free and mature markets, storage plays a commercial role as a trading support tool.

What is natural gas used for?

Unlike oil, gas does not have a dedicated market for its use. It is in competition with other energies.

It is particularly used domestically for heating and cooking. 40% of natural gas consumption in Europe - 21% globally - takes place in the residential/tertiary sector.

Today, the use of natural gas is developing faster in other areas, such as power plants, industry (including petrochemicals) and transport (CNG and LNG fuel), due to its energy efficiency and environmental qualities. 55% of natural gas consumption in Europe is dedicated to industry and the electricity sector. Natural gas is used as a raw material in the chemicals industry, particularly for petrochemicals and refining.

Natural gas has a very favorable environmental footprint when it comes to electricity production. CO2 emissions are half those of the most efficient coal-fired power plants.

Gas-fired power plants are associated with lower investment and operating costs. In addition, they can deliver efficiency performances in excess of 55%, substantially reducing energy consumption and hence global atmospheric emissions.

Moreover, the inherent flexibility in the use of gas power plants ensures perfect complementarity with renewable energies, which, by their very nature, are intermittent.

The electricity sector accounts for 42% of global gas consumption, compared with 36% in 2000. The share of gas in electricity production rose from 18% in 2000 to 24% in 2016

"The inherent flexibility in the use of gas power plants ensures perfect complementarity with renewable energies, which, by their very nature, are intermittent."

Armelle Lecarpentier, economic engineer and gas specialist, IFPEN

Unconventional gases

Shale gas

This gas is produced in the clayey source rock where a percentage of the hydrocarbons (15 to 20%) remains trapped. In order to extract it, it is necessary to “stimulate” the reservoir using hydraulic fracturing and horizontal drilling techniques, making it possible to crack the methane-rich rock over long distances.

The American case

Shale gas exploration and production activities have developed widely in the sedimentary basins of America thanks to improvements in techniques and the falling costs of horizontal drilling and hydraulic fracturing. Thanks to the American shale gas “revolution”, the USA became exporters in 2017 and are now competing with some of the biggest LNG suppliers, such as Qatar and Australia. Other countries have also started shale gas production (Canada, China, Argentina, etc.). Elsewhere, though, environmental concerns have hampered development projects.

Today, American shale gas production represents more than 60% of its natural gas production and almost 13% of global natural gas production.

Coalbed methane

This is methane contained in coal beds. This gas is currently extracted in North America, Australia and China. Production remains marginal in Russia, Asia (India, Indonesia) and Europe.

Tight gas

This is gas trapped in low-permeability sandstone reservoirs. North America is the source of more than 80% of global Tight gas production. Other countries, such as China and Argentina, are producing increasing quantities of these gases.

Methane hydrates

Methane hydrates are a mixture of water and methane that, under certain pressure and temperature conditions, crystallize to form a solid.

The conditions required for methane hydrate stability are found in the upper part of the sedimentary column of polar regions (very low temperature – low pressure) or the upper part of deep offshore sediments (high pressure – low temperature).

3 production techniques have been tested:

- Depressurization: the principle here is to destabilize the methane hydrates by pumping water through the well. The local fall in pressure enables hydrate dissociation and the production of water and methane.

- Thermal stimulation: steam is injected to destabilize the hydrates.

- Inhibitor injection: the hydrate stability curve is modified by injecting methanol.

Estimated resources of these unconventional gases are considerable but their extraction is not currently profitable. A number of international partnerships have been set up to examine the potential for industrial-scale gas hydrate production operations. Research and development programs are also being conducted in several countries. The first gas hydrates have been extracted in Japan and Russia but production remains marginal.

The evolution of natural gas prices and contracts

Long-term contracts with “Take or Pay” clauses (payment for at least the contracted quantities) and the indexation of prices to oil have made it possible to ensure the long-term commercial viability of the gas market, a sector that demands considerable transport investments. This type of contract is evolving to adapt to the needs of an increasingly competitive market.

Market deregulation has led to the development of a “spot” gas market in which gas is traded at a particular instant, day to day. The “spot” price is defined with reference to the gas market and depends on the supply/demand balance. It is the guide price in North America and, more recently, in Europe, where it is a reference for around 70% of gas supplies. Conversely, in Asia, the price of gas continues to be largely determined with reference to the oil market.

“In Europe, the 'spot' price is a reference for around 70% of gas supplies.”

Geoffroy Hureau, General Secretary Cedigaz

The increase in American LNG exports is encouraging the expansion of the spot market and gradually putting pressure on gas price and oil price indexation mechanisms. In addition, today, commercial contracts are variable in duration (spot, short-, medium- and long-term) and can guarantee supply flexibility with a freedom of destination enabling players to take advantage of arbitration opportunities between markets. The globalization of gas markets thanks to LNG is fostering the convergence of international gas prices.

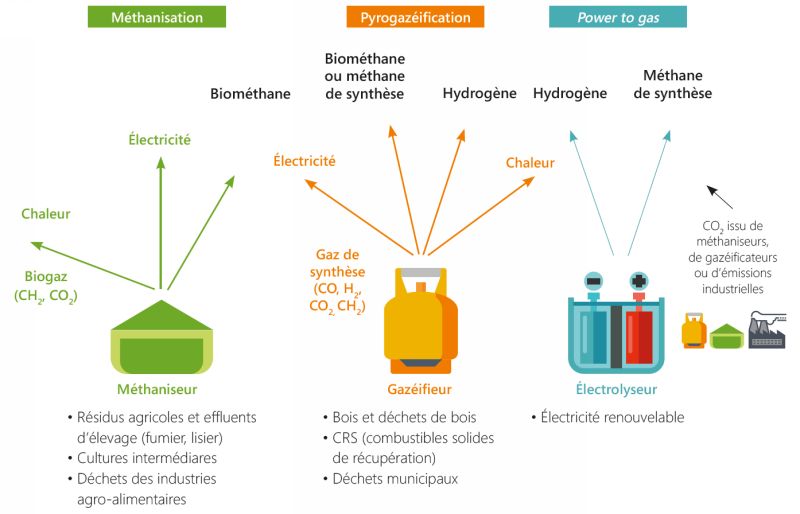

The development of renewable natural gas

Renewable gas, i.e., biomethane, is an alternative to natural gas. Of biological rather than fossil origin, biomethane is a biogas that has undergone a purification step – i.e., the elimination of gases other than methane – to ensure the CH4 content is between 85 and 100%. This biomethane can then be injected into natural gas networks or used as a fuel (bioNGV).

Biogas production is obtained by recovery in non-hazardous waste storage facilities (landfill sites) or by methanization. The former process involves converting non-hazardous waste (from agriculture, industry, household waste, etc.), plant matter and water treatment plant sludge (PSPP).

Other biomethane production processes are in the experimental or demonstration phase, such as gasification of lignocellulosic biomass and power to gas, which is based on the electrolysis of water to produce hydrogen. In these two options, biomethane is produced via methanation by reacting CO2 with hydrogen. The methanization of microalgae may also be a potential solution in the longer term.

Source : AFG

The uses of biomethane are the same as those of natural gas. One of the most relevant uses is as a fuel. The use of biomethane as a fuel in the transport sector would lead to a substantial reduction in pollutant and CO2 emissions in this sector. Moreover, since bioNGV and NGV (natural gas for vehicles) have the same chemical composition, bioNGV can be used in vehicles running on natural gas and to supply filling stations without the need for technical modifications.

Biomethane is an emerging sector that currently only represents a marginal proportion of global gas consumption. But it is a rapidly developing sector, particularly in Europe (including France).