News in brief

Yves Chauvin Prize: Molecular modeling of the solid electrolyte interphase in lithium batteries

The gradual loss of autonomy of lithium-ion batteries, used in our cell phones and electric vehicles, is notably linked to the formation of a layer known as a Solid Electrolyte Interphase (SEI), which builds up between one of the electrodes and the battery electrolyte. The formation of this SEI layer (Figure 1) was studied theoretically in this thesis using molecular modeling to improve the understanding of its thermodynamic and kinetic aspects. The PhD research initially focused on compiling a database of the principal degradation reactions involved by calculating the reaction and activation energies using DFT. The results used in KMC simulations then revealed that salts such as Li2CO3 and Li2O, derived from electrolyte degradation, play a crucial role. Simulations are also used to predict the loss of battery capacity as a function of the initial composition of the SEI layer (Figure 2) and hint the importance of considering other salts such as LiF resulting from degradation...

News in brief

SC2 - Biofuel production: understanding and controlling corrosion by renewable feedstocks

Biofuels are one of the components of the transition to renewable energies, and their use is an effective way of decarbonizing transport. However, they are produced from feedstocks whose composition can affect the steel equipment used for their conversion. For example, the hydrotreatment of vegetable oils and animal fats leads to the exposure to high concentrations of oxygenated compounds, naturally present in the initial feedstock or resulting from their conversion...

Individual page

Rémy MINGANT

Research Engineer, PhD in Electrochemistry

I am Rémy Mingant, an experienced research engineer at IFP Energies Nouvelles, specializing in corrosion, batteries, and materials. My journey is built upon a strong academic foundation, crowned by a

News in brief

SC6 - How to better control loss of lithium battery capacity

Everybody knows that lithium-ion batteries, used in cell phones, computers, etc., gradually lose capacity and eventually fail. This loss of capacity is primarily due to a layer known as the SEI, which forms between one of the battery’s electrodes and the electrolyte (see Figure). This layer already appears after the first battery charge/discharge cycle, and grows over time, consuming lithium ions. The process is irreversible and therefore detrimental to battery capacitye...

News in brief

Self-repair against localized corrosion

Due to their low cost and their good mechanical properties, carbon steels are a widely used material, including for equipments in contact with harsh environments, such as aqueous media containing CO2...

News in brief

Battery behavior: a complexity best taken into account by modeling

For around fifteen years now, IFPEN has been focusing on modeling conventional batteries to represent their nominal operation (electric and thermal behavior during normal operation), throughout their lifetime (...) and in the event of thermal runaway (failure, improper use)...

Individual page

Jean KITTEL

Materials & Corrosion Technical Advisor, Project manager

PhD in Electrochemistry

PhD in Electrochemistry

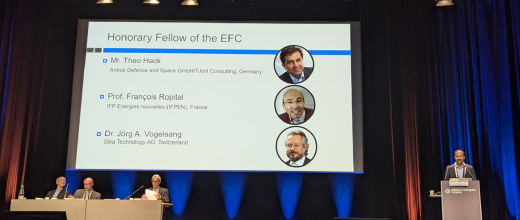

> 20 years experience in Materials and Corrosion. Materials Engineer from INSA de Lyon, 1997. PhD in Eectrochemistry (Paris 6), 2001. Habilitation from INSA de Lyon, 2011. Member of Cefracor / EFC /

News in brief

Carbon steel in self-defense mode against corrosion

Carbon or low-alloy steel corrosion, by aqueous media containing CO 2, hampers the development of numerous technologies a for the energy transition. Among the electrochemical processes involved, the