11.05.2022

15 minutes of reading

In the context of an energy environment in full transition, the Catalysis, Biocatalysis and Separation division is redoubling its research efforts on innovation. Alongside applications within IFPEN’s traditional scope, the Institute’s drive for diversification over several years is beginning to bear fruit, with major benefits in new energy technologies (NET), such as catalysts or biocatalysts for the production of bioproducts or biofuels (biobutadiene, biochemical production of ethanol), and separation agents for the extraction of lithium. This ongoing effort is part of IFPEN’s new strategic priority “Climate, Environment and Circular Economy”.

To capitalise on the results of this research, IFPEN has relied on a strategy of solid industrial property, with 273 patents filed during the 2016-2020 period (42% of them in NET).

With the aim of offering new technological solutions, this innovation strategy is based on fundamental research, which is critical in overcoming a number of knowledge barriers, such as the understanding of new reaction mechanisms, exploration of new catalysts, photocatalysts and separation agents, decoding biocatalysts. Digital technology is also opening up significant avenues for improvement, with the improved visualisation of experimental data and quantum molecular modelling approaches combined with artificial intelligence.

The scientific merit of this research has been supported by the many papers published from 2016 to 2020, in connection with national and international academic partnerships, and with the recognition of 12 prestigious awards in the same period.

The division has also implemented a highly proactive policy of outreach, playing a role in national and international networks, contributing to a range of collaborative projects (national and European), and steering an industrial chair financed jointly with IDEXYLON.

This special edition of Science@ifpen highlights the recent scientific achievements made by the division in a number of priority areas of its fundamental research.

Luc Nougier

Director of Catalysis, Biocatalysis and Separation

Pascal Raybaud

Scientific Assistant to the Director of Catalysis, Biocatalysis and Separation

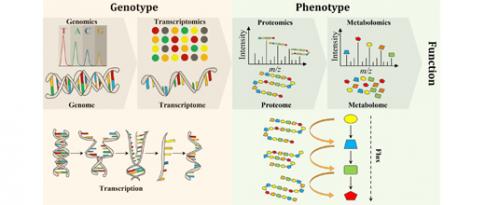

The “Omics”, seven hired hands working for biotechnology

Most frequently, the use of a microorganism in the production of biofuels or biosourced chemicals requires its optimisation. This is achieved through genetic engineering, which involves inactivation and/or addition of one or more genes, to improve the ability of this microorganism to produce a target molecule. (...) At IFPEN, access to genomics (DNA) has helped in gathering data on the composition and structure of the genomes of the microorganisms...

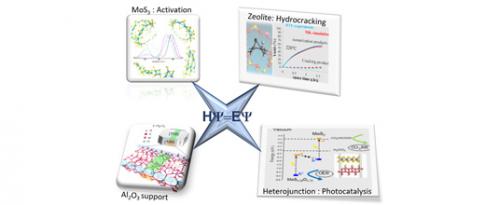

Molecular modelling: a key tool for current and future heterogeneous catalysis

Chemical theory at quantum level (density functional theory or DFT) is an essential tool in rationalising the reaction mechanisms involved in the preparation of catalysts, as well as in their use, thanks to the optimisation of their activity [1,2]. IFPEN has carried out a number of projects aiming to shed light on these catalysts, which are of particular interest to industrial processes...

Photocatalysis, a lighted pathway for CO2 conversion

Although the climate crisis makes the reduction of CO2 emissions a matter of urgency, some industries will have difficulty in avoiding them, such as cement plants (where the core process is currently based on the calcination of CaCO3) or refineries, which are currently highly energy-intensive. Hence the huge potential interest in procedures that could capture the CO2 released directly from the plant (...) then recover it at a fraction of the energy cost...

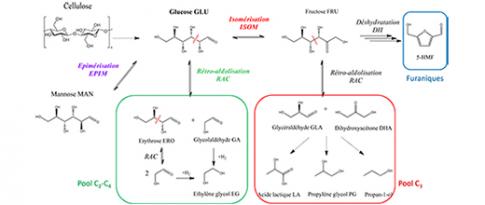

Experimentation and modelling combined to study the catalytic conversion of biomass-derived sugars

Driven by the global challenge of switching to a more sustainable economic and energy model, IFPEN has been studying for a number of years biosourced products with high added value and working to develop processes for biomass recovery, as an alternative to conventional petrochemistry.

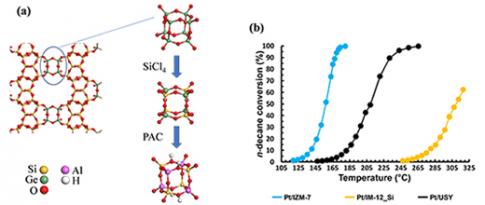

New acid zeolites obtained from silicogermanates

Zeolites are microporous crystalline aluminosilicates that exist in the natural state and can also be synthesised for a wide range of applications, from the biomedical industry to the production of renewable energy. (...) This work was carried out entirely at IFPEN as part of a doctoral thesis and has resulted in a new stable zeolite...

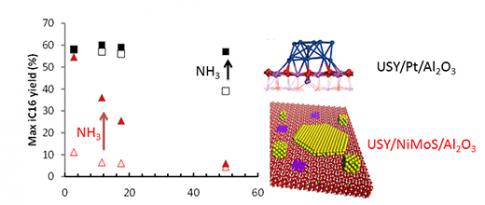

Bifunctional catalysis deployed for the production of biofuels

The production of biofuels, renewable diesel or sustainable aviation fuel can be achieved through lipid feedstocks conversion, such as vegetable oils, used cooking oils or animal fats. Through a hydrotreatment stage, we obtain long-chain normal paraffinsa, which must then be isomerised or cracked in order to adjust the properties of the effluent, resulting in the specifications required according to the targeted fuel type (particularly cold flow properties and/or final distillation temperature)...

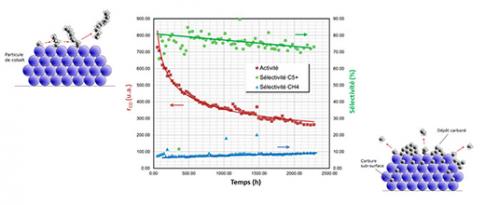

Loss of selectivity in Fischer-Tropsch synthesis: a high-throughput study

Faced with the current climate challenges, alternative fuels are attracting a growing interest for the mobility of the future. Of the various possible alternatives, hydrocarbons could be synthesised via a well-known process: the Fischer-Tropsch (FT) process, based on Syngas (CO and H2) produced, in particular, by biomass gasification. (...) However, the deactivation of FT catalysts is a major issue that directly impacts the costs of the process. (...) To identify these mechanisms, a multiple-stage methodology was implemented as part of a doctoral thesis...

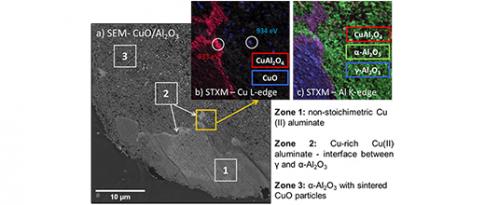

The premature ageing of oxygen carrier materials: a challenge for CLC

The increase in the level of atmoshpheric CO2 and the resulting climate change are a global concern. Despite this, the use of fossil fuels continues to grow, in response to high energy demand. Combined with storage and CO2 conversion solutions, Chemical Looping Combustion processes (CLC) offer a medium-term solution to reducing the impact of energy production from fossil fuels, or even biomass...