Bio-based chemistry

Our solutions

IFPEN is working on the development of new processes, catalysts and biocatalysts for the conversion of lignocellulosic biomass and the production of key bio-based chemical intermediates, which are more environmentally-friendly than the same fossil-based products and address the growing need to reduce industrial greenhouse gas emissions while offering a diversification of supply sources.

Summary:

- Olefin production from bio-alcohols

- Bio-butadiene production

- Bio-aromatics production

- Bio-based alcohol production

- Bio-acrylic acid production

OLEFIN PRODUCTION FROM BIO-ALCOHOLS

In partnership with TotalEnergies and Axens, IFPEN has developed a process and a catalyst for the production of bio-based olefins. Atol® is an original and competitive technology that makes it possible to produce bioethylene via the dehydration of renewable ethanol from the fermentation of non-food lignocellulosic biomass. The bioethylene produced can be directly integrated into existing polymerization units, to produce polyethylene, polystyrene, PET or even polyvinyl chloride. Optimized in terms of energy efficiency and with an excellent performance in terms of activity and ethylene selectivity, Atol®, which is marketed by Axens, is considered to be the most advanced and most profitable dehydration technology available on the market, with low investment and operating costs.

In 2022, the guaranteed performance for a reference of Atol® technology was achieved with flying colors at Sumitomo Chemical’s first pilot plant (Japan) for a circular economy deployment project in Japan involving the conversion of ethanol, produced from household waste, into polymer-grade ethylene. It will then be converted in the facilities into polyethylene, a key product for the manufacture of numerous bio-based plastic items.

In 2023, the first European plant based on Atol® technology was opened.

In addition, IFPEN is conducting research aimed at developing processes to convert sugars into bio-based intermediate molecules for the manufacture of polymers and other bio-based products.

Atol® technology is one of the technological building blocks for biojet production using the Alcohols To Jet process.

BIO-BUTADIENE PRODUCTION

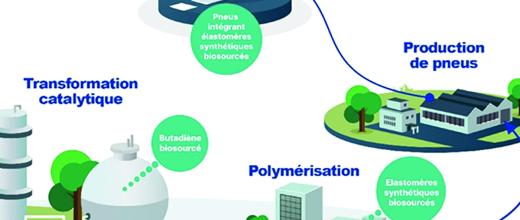

The BioButterfly project is aimed at developing a butadiene production process using fermented ethanol of plant origin. Supported by the French environment and energy management agency Ademe, the project brings together Axens, IFPEN and Michelin and is being conducted as part of a strategy to create a French bio-based synthetic rubber sector for the manufacture of tires.

Thanks to biomass from plant residues (wood, rice husks, leaves and cornstalks), Michelin estimates that 4.2 million metric tons of wood chips could be incorporated in their tires each year. Watch a video explaining Michelin’s recipe to design fully sustainable tires by 2050.

The BioButterfly project was launched in 2012 and has since achieved a number of technical and economic milestones. The project actually covers all the research and development phases for a butadiene production process, from fundamental scientific concepts through to validation of the various catalysis and separation operations on an industrial demonstrator. Its budget is close to 80 million euros.

In January 2024, the first scale-up pilot for butadiene production from bio-based ethanol was commissioned. Production of bio-based butadiene began in July, and several metric tons have been produced since then. This pre-industrial experimentation unit will enable IFPEN to validate the operation of the process and the quality of the butadiene. The technical performance obtained will provide the data for a technical and economic study and a life-cycle analysis that are required to validate the industrial and societal benefits of the process.

BIO-AROMATICS PRODUCTION

In 2015, IFPEN and Axens joined forces with American company Anellotech to develop Bio-TCat, an innovative bio-aromatic production technology (BTX for benzene, toluene and xylene) based on renewable raw materials. By coupling a thermocatalytic conversion process for non-food lignocellulosic biomass from Anellotech with hydrotreatment processes from Axens, the aim is to produce – at low cost – large quantities of purified bio-aromatic compounds that are used in the manufacture of plastics (PET, polyesters, polystyrene, etc.), which form the basis of many consumer goods. The technology can also provide the biofuels industry with a high-quality gasoline base.

The TCat-8® pilot unit installed at Anellotech’s site in Silsbee (Texas) has been operating since 2017, demonstrating the technological and economic viability of thermocatalytic conversion.

In February 2019 Anellotech, IFPEN and Axens announced that they had not only successfully produced bio-based aromatics but that they had also achieved “polymer-grade” qualities for bio-based para-Xylene.

By early 2021, the work was completed. They notably focused on economic assessments of the technology, product post-treatment solutions and the production of 90 kg of para-Xylene from the pilot unit operated in Texas, in preparation for the manufacture of the first batch of 100% bio-based PET bottles.

The final qualification of para Xylene derived from the Bio-TCat™ process was validated at the end of 2021 with the production of the first 100% plant-derived PET bottle prototypes by the Japanese company Suntory, a major global player in the manufacture and distribution of consumer beverages.

Validation of the Bio-TCat™ technology was completed with the production of a process data book by Axens, which is now taking steps to industrialize and market it, thereby paving the way for the construction of a first commercial unit.

In September 2022, the Plastics Industry Association awarded the 2022 innovation prize in the field of bioplastics to American company Anellotech for its contribution to the development of the first 100% bio-based PET bottle.

BIO-BASED ALCOHOL PRODUCTION

In addition to ethanol production from non-food lignocellulosic biomass using the Futurol™ process recently marketed by Axens, IFPEN is conducting research to develop biotechnological processes for the production of bio-based propanol and butanol. A stable microorganism has been developed and an innovative implementation approach tested on a 100-liter scale. R&I work is continuing to optimize the various building blocks of the process with a view to creating a process that can be taken to market.

Bio-acrylic acid production

IFPEN, Cargill and Axens joined forces to launch a project for the development and industrial scale-up of a catalyst and process to convert a lactic acid into a bio-based acrylic acid of plant and renewable origin. This conversion process resulted from a technology developed in the laboratory by Procter & Gamble and for which Cargill obtained an exclusive license at the beginning of 2020. The use of bio-based acrylic acid, a raw material that is contained in numerous everyday products such as acrylic glass, adhesives and super-absorbent polymers, will contribute to the development of the bioeconomy and lead to a reduction in greenhouse gas emissions by more than 50%.

“The catalyst and process that will be developed are based on a conversion technology that has already been tested in the laboratory. However, a number of significant challenges still need to be overcome prior to industrial scale-up. Each partner will have a decisive role to play: Cargill will contribute its experience in the field of bio-based materials, IFPEN will draw on its expertise to focus on the development of the catalyst and the conversion process required for the large-scale conversion of lactic acid into bio-based acrylic acid, and Axens will facilitate industrial scale-up in line with existing environmental standards