Energy storage

Energy storage

Our solutions

The energy transition will depend on a significant increase in the production of renewable electricity, particularly generated by wind farms and photovoltaic panels. The specific feature of these two technologies is that they depend on weather conditions, implying variable production that cannot be managed. Consequently, there is a potential lack of synchronization between electricity production and demand. In order to maximize the share of renewable energies in the energy mix, IFPEN proposes technological innovations for the integration of variable renewables in the networks, thereby supporting the development of technically and economically viable energy storage sectors.

Energy management systems

Energy storage can provide a variety of services to the grid (peak shaving or arbitrage): depending on their specific characteristics (investment and operating costs, yield, acceptable depth of discharge, etc.), the various storage technologies vary in their suitability to meet these needs. IFPEN is developing a multi-criteria analysis approach capable of identifying the best technical solutions in terms of their economic and environmental challenges. Its research activities incorporate the simulation of the system concerned throughout its life span and are hinged around the capacity to develop Energy Management Systems (EMS).

An EMS is a system of computer-aided tools designed to optimize the performance of energy systems, applying strategies making it possible to fully exploit a storage system within a specific network. Such systems are of interest in contexts as diverse as individual or collective self-consumption, grid services and multi-energy industrial sites.

IFPEN’s expertise in the fields of optimization mathematics, data science and system control, combined with the performance of our testing facilities enable us to develop energy management systems with a view to proposing several types of services:

• maximize the rate of self-consumption for professional users equipped with solar panels and a battery. With our partner Soalis, we offer an EMS that manages the battery to optimize consumption and solar panel production, thus reducing the energy bill of equipped customers. Our EMS has been tested on one of the buildings at our Lyon site, enabling us to validate our solutions in real operating conditions. Our long-established battery modeling expertise enables us to incorporate storage battery aging into the calculations and our optimization algorithms ensure optimal management in order, for example, to maximize individual self-consumption rates.

• foster the emergence and profitability of collective self-consumption energy community projects. We are working on optimization services and energy distribution calculations for energy communities based on machine learning models.

• support the electricity grid by aggregating diffuse batteries and using them as a system service to the grid, either as an energy reserve (capacity reserve) or as grid support (primary and secondary reserve). These aggregated algorithms can also minimize the CO2 footprint of grid offtake. Our work with electricity aggregators such as Urban Solar Energy enables us to test various optimization methods based on the simultaneous resolution of thousands of scenarios.

The EMS-lab@ifpen cloud platform provides real-time monitoring and control of sites equipped by IFPEN's partners. Production and consumption forecasts and optimization scenarios are therefore automatically managed.

Advanced adiabatic compressed air energy storage (AA-CAES)

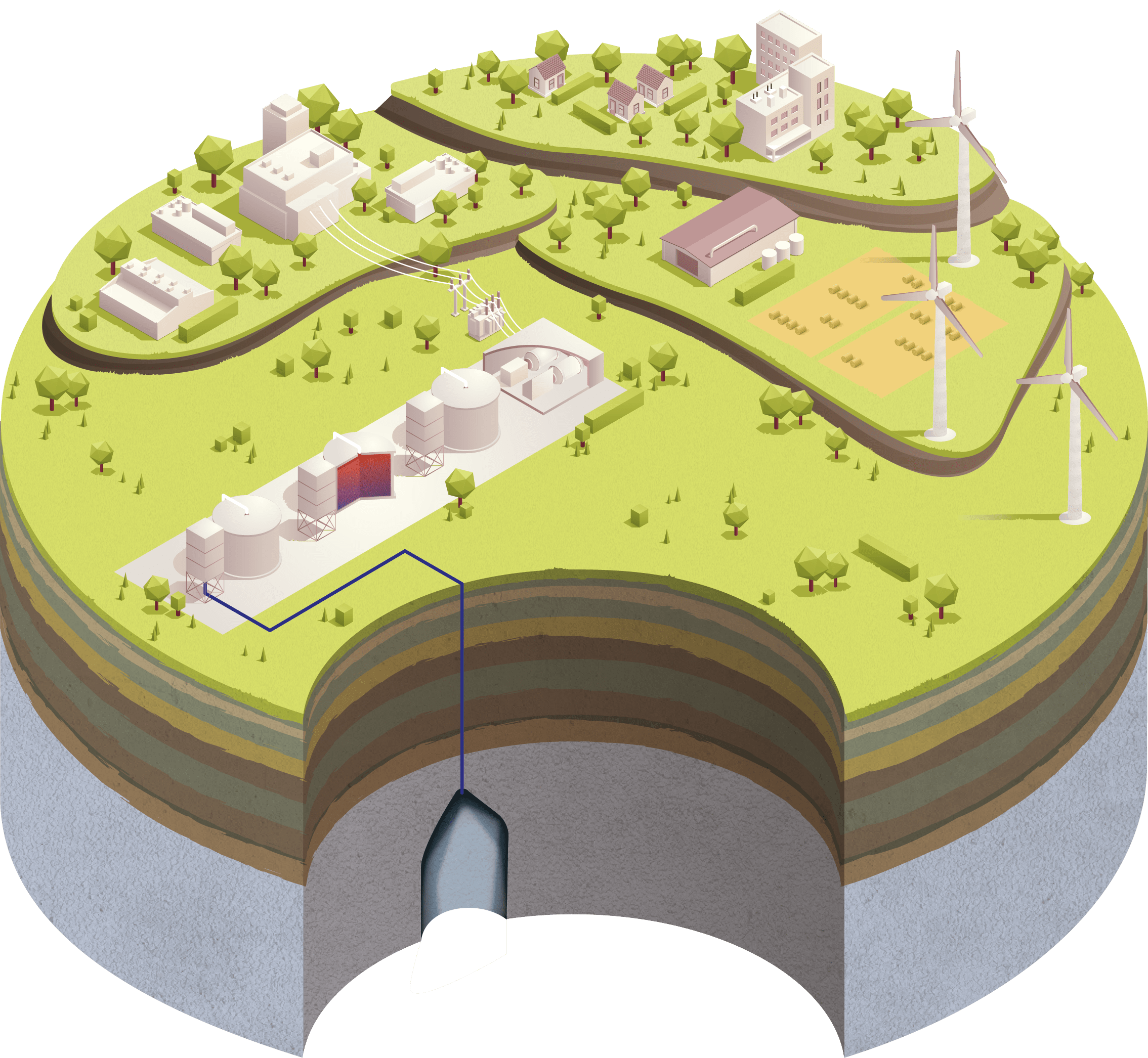

Compressed air energy storage has existed since the 1970s (the Huntorf power plant in Germany was commissioned in 1978) in the form of enhanced gas plants with a maximum energy efficiency of 50%. In these old Compressed Air Energy Systems (CAES), the heat produced by compression is lost. A more sophisticated concept is Advanced Adiabatic Compressed Air Energy Storage (AA-CAES): this solution makes it possible to store compression heat and achieve a far higher degree of efficiency.

Using the AA-CAES principle, IFPEN is developing a system:

• based on a maximum of off-the-shelf components, such as compressors and turbomachines,

• proposing innovative solutions, for components that do not yet exist, such as TES (Thermal Energy Storage) systems.

It operates as follows:

• storage is based on air compression and heat storage,

• to release the stored energy, air is passed through turbines following re-heating via the recovery of stored heat.

Storage is cavity-based, offering the advantage of being more efficient and cheaper than surface-based storage, which would require more substantial equipment.

Storage could also be based on pipeline networks, which is an interesting solution in terms of reusing existing networks.

Our R&D developments are focused on two aspects:

- The choice of efficient heat storage systems

- Process optimization

- Improved management of heat transfers during air compression and expansion phases

- Choice of pressure ranges

- Use of innovative materials

We are also working with partners on quasi-isothermal compression technologies to avoid the need for heat management.