BiofuelS and e-fuels

OUR solutions

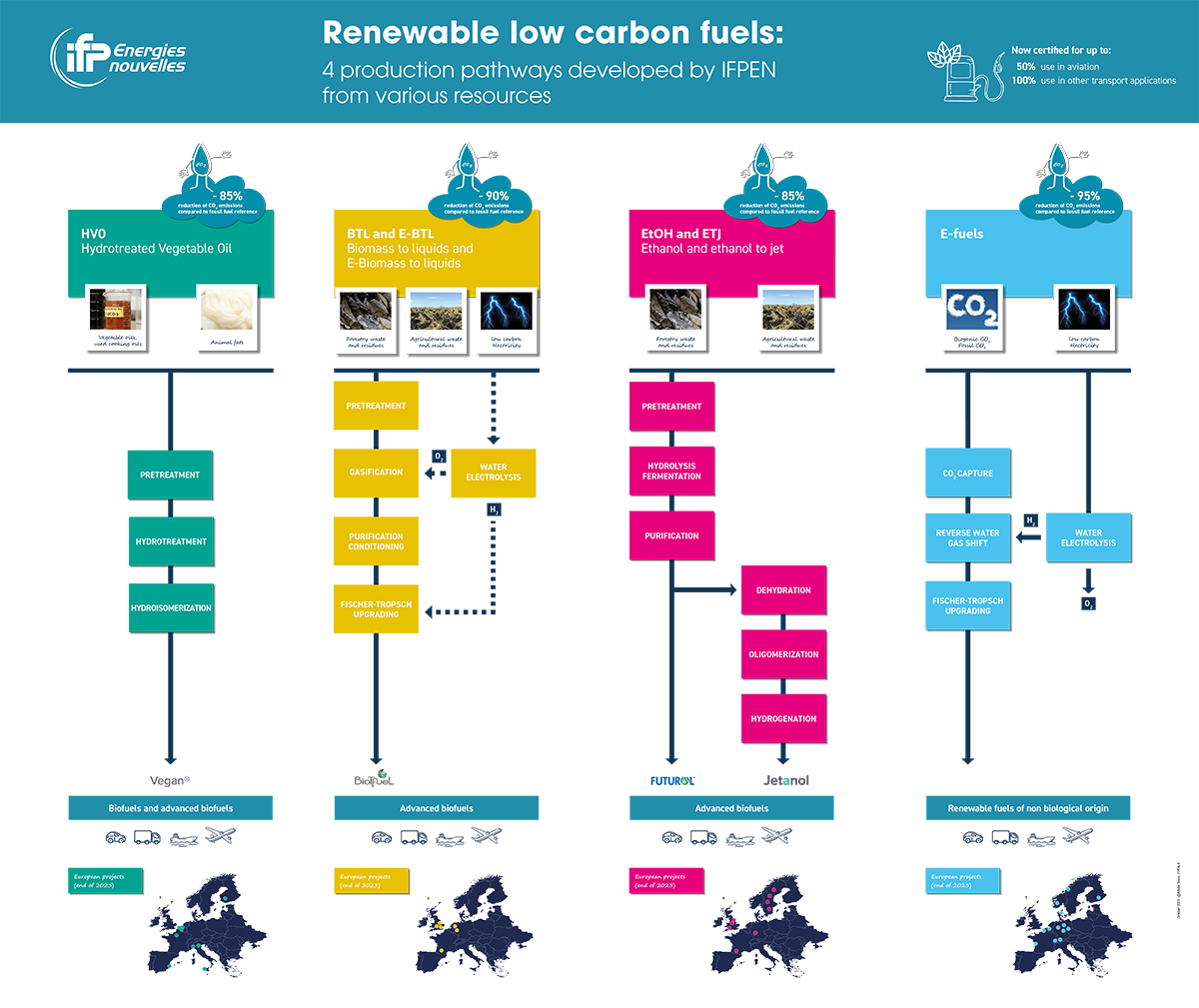

IFPEN is actively involved in the development of four technologies targeting the production of biofuels and e-fuels to meet the needs of the road, aviation and maritime sectors. The technologies cover the entire value chain, from the conversion of a diversified pool of resources through to the production of low-carbon liquid fuels.

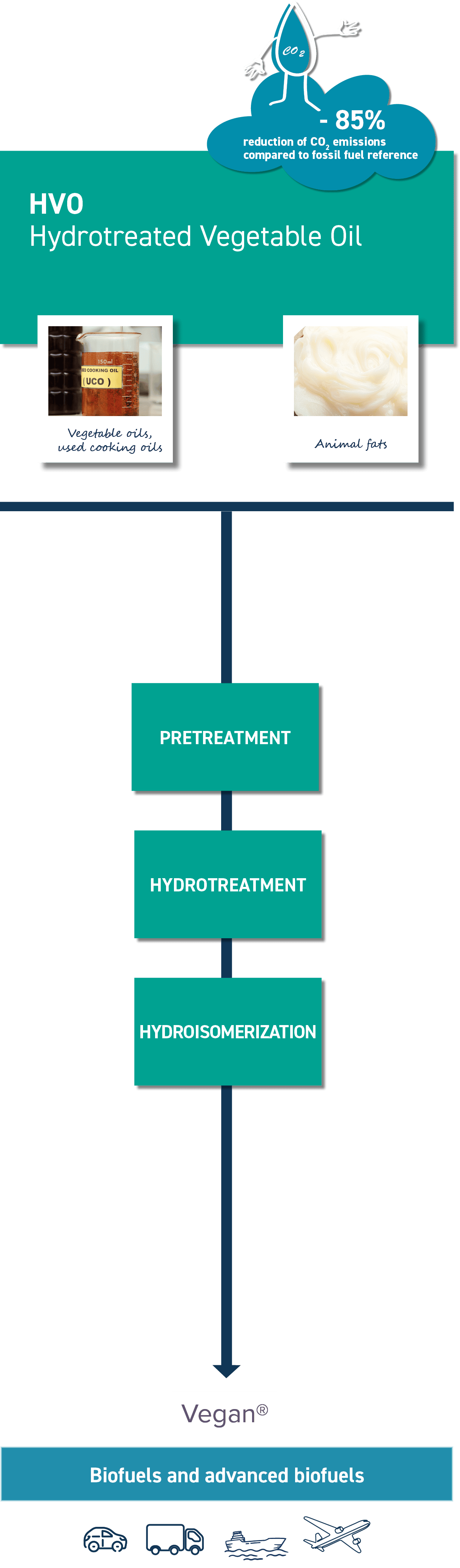

The hydrotreatment of vegetable oils (HVO) with Vegan™

IFPEN developed the Vegan® process dedicated to the hydrotreatment of vegetable oils (vegetable oils, waste cooking oils, residues from the production of food-grade vegetable oils, animal fats, etc.) marketed by Axens.

Licenses for the Vegan® process have already been granted worldwide, including one in France at the Mède TotalEnergies site.

Teams are continuing their R&I work with a view to optimizing the process, particularly in terms of reducing the energy consumption, increasing kerosene yields and using a broader range of feedstocks.

Click here to find out more about Vegan®

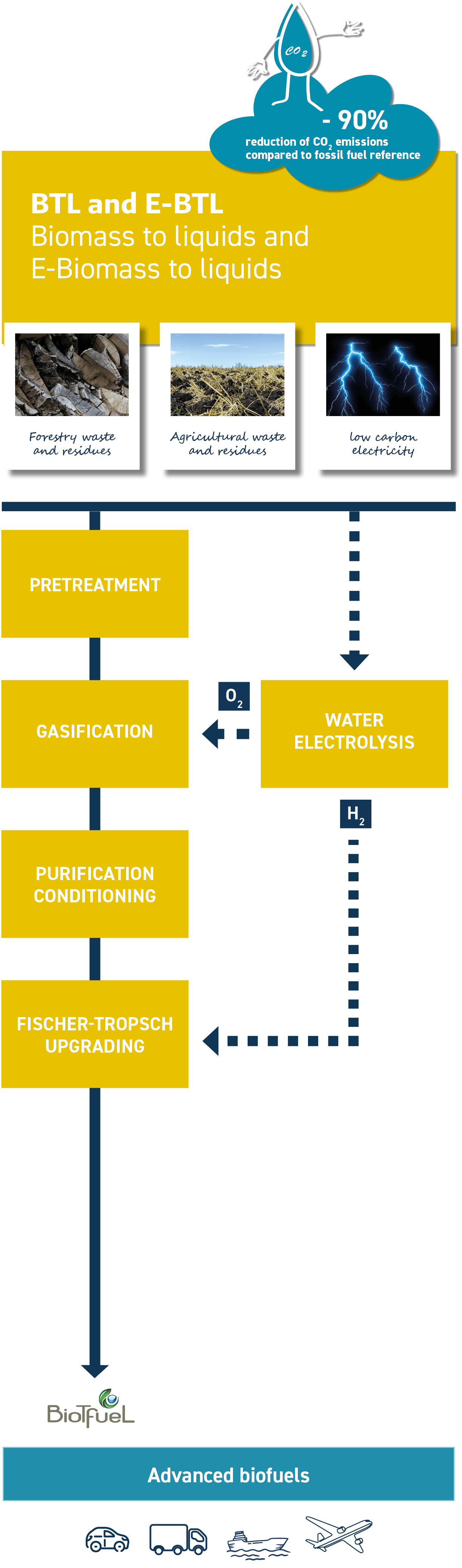

BTL and E-BTL with BioTfuel®

Between 2010 and 2021, IFPEN developed the BioTfueL® process with its partners Avril, Axens, the CEA, TotalEnergies and ThyssenKrupp Uhde. BioTfueL® is an advanced biofuel production technology based on a thermochemical process (gasification of biomass and conversion into fuels via Fischer-Tropsch synthesis), using a broad range of lignocellulosic biomass resources (agricultural and forestry waste).

Successfully demonstrated on a pre-industrial scale, BioTfueL® technology is currently the focus of engineering studies for industrial scale-up.

For example, the BioTJet project concerns the construction and operation of a French advanced biokerosene industrial production unit, based on this innovative technology. BioTJet combines BioTfueL® technology with the injection of low-carbon hydrogen, obtained via water electrolysis, which will double the quantity of kerosene obtained for the same amount of biomass consumed. The majority of the biomass used will come from local forestry waste.

Led by Elyse Energy and supported by ADEME, BioTJet brings together IFP Investissements (an IFP Énergies nouvelles subsidiary), Axens, Avril and Bionext. Located in the Lacq industrial basin, this new plant is expected to be supplying 75, 000 tons per year of sustainable aviation fuels (SAF) by 2028, i.e., around 15% of total French demand.

Click here to find out more about BioTfueL® Click here to find out more about BioTJet

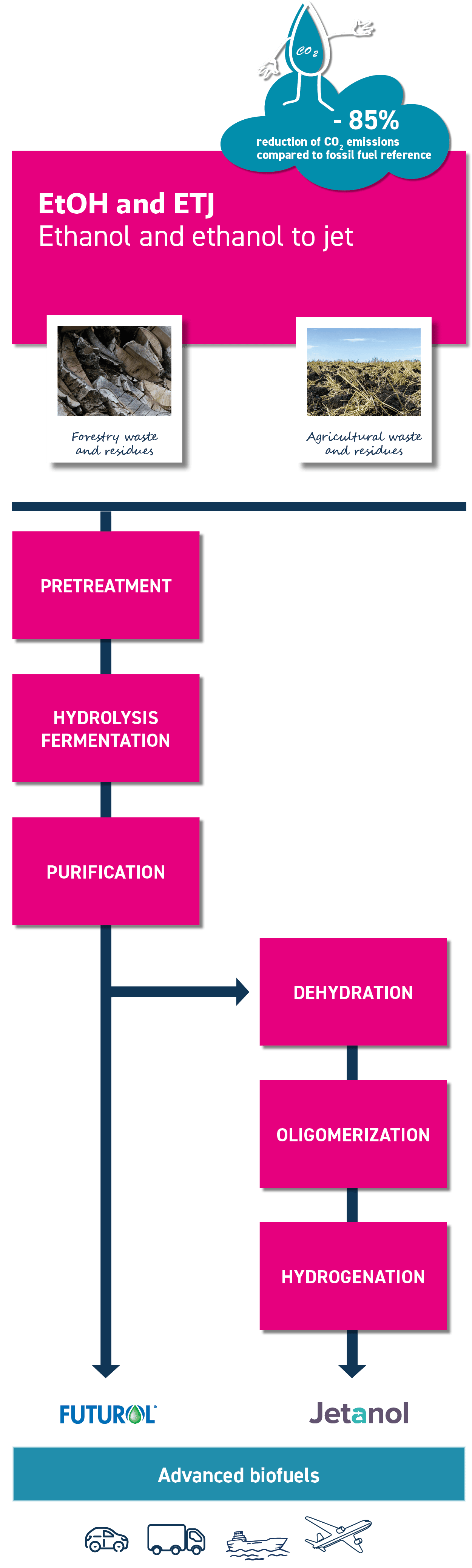

Bioethanol with Futurol™ and Jetanol™

Between 2008 and 2018, IFPEN developed Futurol®, a technology dedicated to the production of advanced ethanol, within the framework of a collaborative project bringing together 11 partners from the worlds of research, industry and finance. The Futurol® process is now marketed by Axens. A first license for the process was granted to INA in Croatia in 2020.

A project for the construction of an advanced ethanol production unit in France, based on Futurol® technology, is currently under consideration.

IFPEN also developed the Jetanol™ suite of processes making it possible to convert advanced bioethanol from Futurol® into biokerosene. Axens has granted three licenses for the Jetanol™ suite worldwide.

Click here to find out more about Futurol®

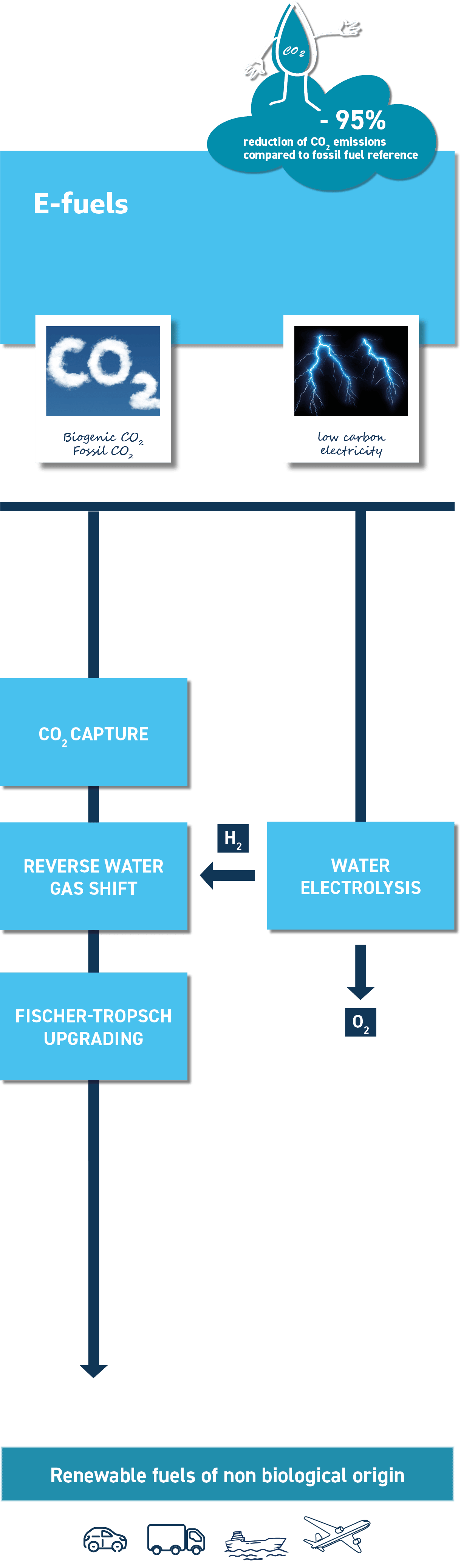

Toward an E-Fuels sector

The technological maturity of the various processes behind the production of e-fuels from CO2 and low-carbon hydrogen is different. IFPEN is developing the technological building blocks required for each step in the chain:

- Fossil or biogenic CO2 capture. IFPEN is developing two CO2 capture processes, one based on a demixing solvent, the other based on chemical looping combustion. These processes are currently at the industrial pilot stage.

Find out more about IFPEN’s technologies in the field of CCUS and CO2 capture

- The conversion of CO2 into CO requires low-carbon hydrogen obtained via water electrolysis, the RWGS block. IFPEN is conducting R&I to take the process to the pre-industrial scale.

- Fischer-Tropsch synthesis. IFPEN and Eni have been developing the Gasel® process, dedicated to the production of synfuels from CO and H2, since the 2000s. This process is marketed by Axens.

Located at a site in the Pays de Loire region of north-western France, the “Take Kair“ project, bringing together EDF, IFPEN and Axens, is aimed at constructing an e-kerosene industrial pilot in 2028. It will be one of the first e-kerosene production units in the country and will contribute to the emergence of a new industrial e-fuel sector for aviation. Axens and IFPEN will contribute their expertise in the development and integration of low-carbon fuel synthesis processes and their experience in SAF production technologies.