Basins and reservoirs modeling and simulation

Basins and reservoirs modeling and simulation

oUR solutions

IFPEN develops innovative underground modelling and simulation solutions, both at the scale of sedimentary basins and at the reservoir level. These different solutions can be used to manage uncertainties related to underground exploration and exploitation and to reduce risks.

The results of IFPEN’s research and development are transposed into software, marketed by its partners. IFPEN and its partners also offer collaborative research in the form of JIP and communities, as well as custom-designed studies and services.

IFPEN’s work is based on an approach that extends from the microscopic analysis of rock and fluid properties to modeling at the basin or reservoir level. This approach, which combines different disciplines and expertise, associates fieldwork with laboratory studies using state-of-the-art equipment, some of which is custom-built, and is complemented by modeling work.

Find out more about IFPEN’s expertise and state-of-the-art equipment.

MODELING AND SIMULATION : A WIDE RANGE OF SOFTWARE

Basin modeling

The software derived from IFPEN’s research focuses on stratigraphic modeling (DionisosFlow™), oil system modeling (TemisFlow™), kinematic modeling using numerical methods (KronosFlow™, Kine3D®) or analog methods (GeoAnalog™). The tools integrate research on various topics such as fluid migration in fractured systems and complex tectonic processes.

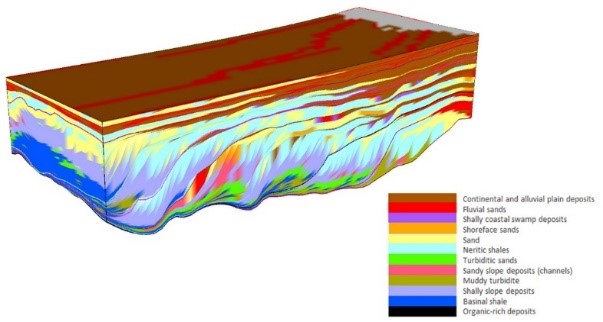

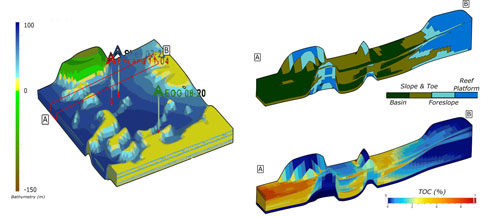

DionisosFlow™ : model sedimentary basin filling

DionisosFlow™ methodology, developed by IFPEN over the past 20 years, consists of modeling sedimentary processes and providing an evolving 3D numerical grid that represents the geometry and nature of the basin’s sedimentary layers, and provides quantitative indications on specific rock properties.

The result of the research and development conducted by IFPEN are transferred in the DionisosFlow™ software marketed by Beicip Franlab. Additionaly, IFPEN and its partners under DionisosFlow™ also provides R&D, technical consultancy and technical project engineering studies for others in the field of sedimentary modeling.

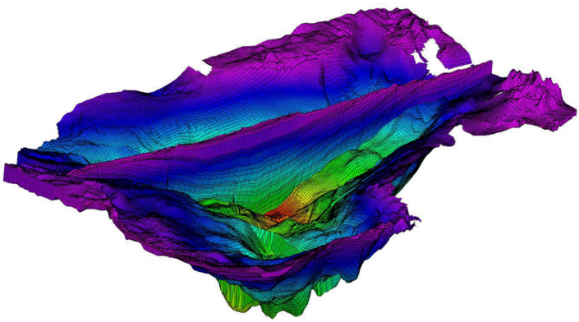

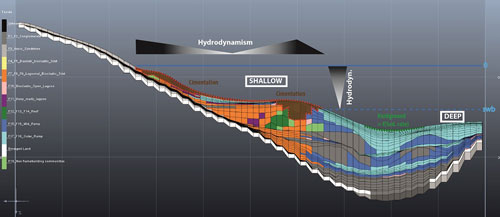

TemisFlow™ : simulate the dynamics of oil systems

TemisFlow™ is an integrated tool for dynamically simulating the evolution of sedimentary basins and the associated oil systems over geological time periods. It can be used to understand and model oil and gas generation, production, migration, trapping and accumulation processes. TemisFlow™ is marketed by Beicip Franlab.

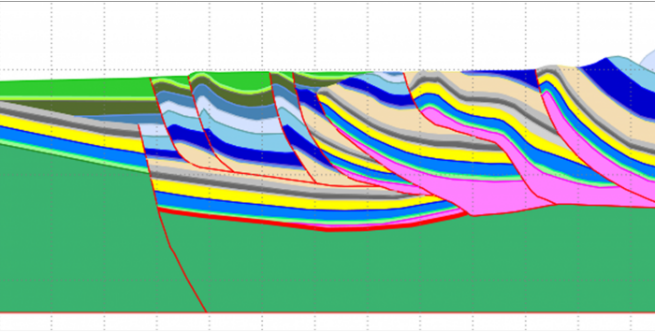

KronosFlow™ : carry out 2D kinematic restoration of basins

KronosFlow™ facilitates the creation of 2D kinematic scenarios to evaluate oil systems in complex geological environments, and can be used to depict phenomena such as the occurrence of high pressures, heat transfer, hydrocarbon accumulation in traps and fluid migration. The mesh evolves over time to faithfully reproduce the deformation in porous media over a geological time scale. KronosFlow™ is part of the TemisFlow™ solution marketed by Beicip Franlab.

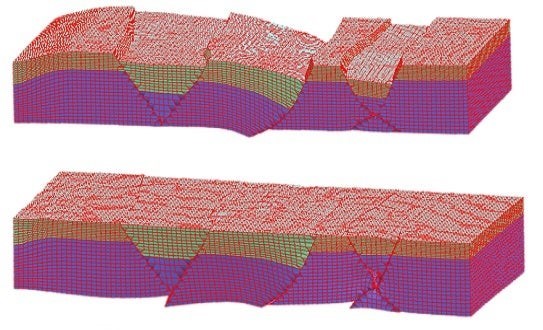

Kine3D® : optimize geological interpretation

Kine3D® facilitates the 3D restoration process, by applying geological, lithological and geomechanical parameters to restore models to their non-deformed state. This process is used to validate structural seismic interpretations and geometries, by incorporating geological constraints. Kine3D® is incorporated into the SKUA® suite marketed by the partner Emerson.

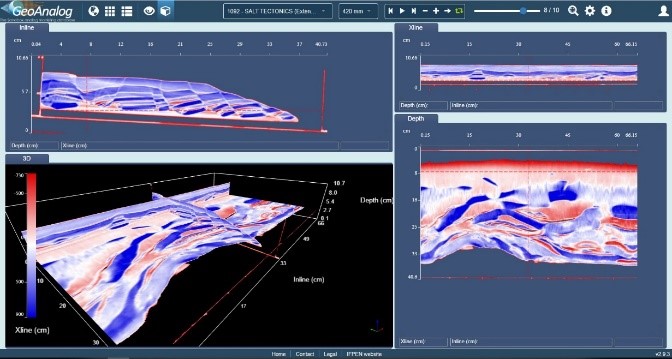

GeoAnalog™ : a digital tool to understand complex geological processes

GeoAnalog™ is a web service aimed at providing a better understanding of the deformation of complex geological structures over time and at helping to interpret seismic data. This service provides access to a catalogue of analogue models acquired in over 1,500 laboratory experiments conducted over 30 years. The web service is available through subscription. New models can also be produced on request by contacting IFPEN.

Modeling and simulation of reservoirs

Software derived from IFPEN’s research focuses on well data analysis (EasyTrace™), fractured reservoir characterization (FracaFlow™), dynamic reservoir simulation (PumaFlow™) and finally, simulation of the thermodynamic behavior of oil fluids (Carbone™). Objective: enhance the reliability of reservoir models to improve productivity.

EasyTrace™ : analyze well logging data

EasyTrace™ is a multidisciplinary 1D data processing and editing tool, featuring a wide range of functionalities within the same package, for geologists, geophysicists and reservoir engineers. EasyTrace™ is marketed by Beicip Franlab.

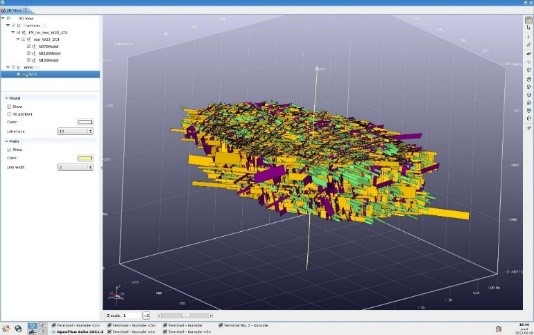

FracaFlow™ : model fractures in a reservoir and study the associated uncertainties

FracaFlow™ provides an integrated workflow for characterization, modeling and dynamic calibration of fractured reservoirs. It comprises dedicated modules ranging from the analysis and integration of geological data to fracture modeling with a discrete fracture network (DFN) and dual porosity media upscaling for reservoir simulation. FracaFlow™ is marketed by Beicip Franlab.

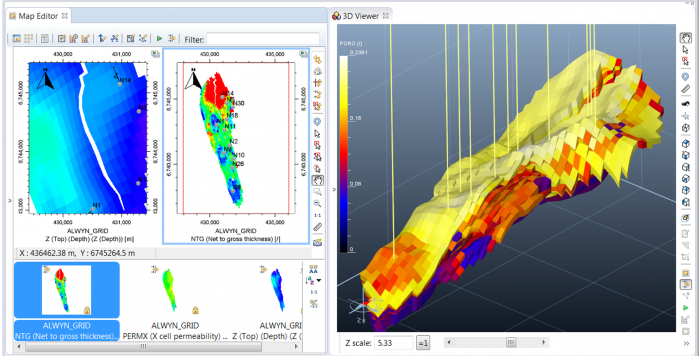

PumaFlow™ : simulate the life of the reservoir and recovery scenarios

PumaFlow™ is a dynamic simulator to predict and optimize hydrocarbon production for all recovery processes. It is based on mathematical models of fluid circulation during production (hydrocarbons and associated fluids, such as water or CO2) and injection. This reference solution for fractured reservoirs (dual medium simulation based on a rigorous formulation of matrix-fracture exchanges) is used by the EOR Alliance and marketed under a partnership between IFPEN, Beicip-Franlab and KAPPA.

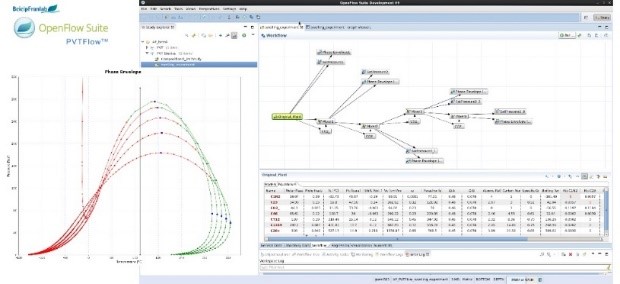

Carbone™ : characterize the thermodynamic behavior of oil fluids

Carbone™ integrates a complete thermodynamic library capable of processing laboratory data to simulate the thermodynamic behavior of oil fluids in order to support field production simulation models. Carbone™ is marketed under a partnership with IFPEN, Beicip-Franlab and KAPPA.

Uncertainty management and calibration

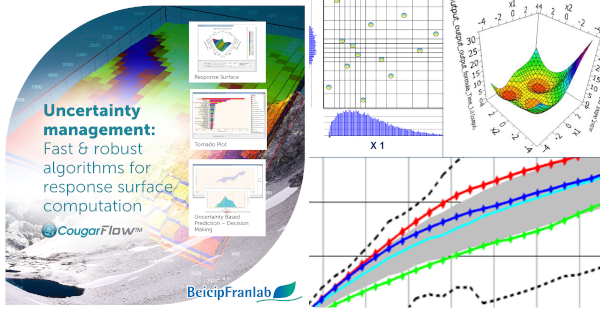

CougarFlow™ : quantify uncertainties, optimize models and analyze the associated risks

CougarFlow™ combines experiment program design and response surface methodologies, which facilitate uncertainty quantification and model optimization. It is widely used in reservoir modeling, and can also be used in basin modeling to improve models. CougarFlow™ is marketed by Beicip-Franlab.

JIP AND COMMUNITIES : ADVANTAGES

IFPEN organizes and coordinates JIPs (Joint industry projects), collaborative research projects bringing together several industrial partners who cooperatively finance a program designed to solve a specific problem. With this format, the financial risks are shared upstream and research results are shared downstream. This collaboration provides a platform to explore avenues leading to innovations and offers partners a genuine competitive advantage by giving them fast access to new technologies. IFPEN is coordinating JIPs in partnership with more than 30 national and international companies.

JIP DORS (Dionisos Organic-Rich Sediments) : understand the production, decomposition and preservation of organic matter

The first phase of the JIP (DORS 1) focused on developing base modules to model organic matter production and decomposition processes in various environments (marine, land and lacustrine). The second phase, DORS 2, aims to calibrate the marine organic matter module on the basis of geochemical proxies, improve the link to oil system modeling, and describe the influx of nutrients resulting from underground leaching and transported in underground water flows into lakes.

>>See « Dionisos organic-rich sediments: DORS 2 » sheet

JIP CarDIO (Carbonate early diagenesis - DionisosFlow™) : understand and model the transformation of carbonaceous sediments in rocks under the effect of diagenetic processes

This JIP aims to model the early diagenesis of marine and coastal carbonates: the development of physical laws for different diagenetic reactions (cementation, dissolution, etc.) in different subsurface environments (marine, lacustrine, hypersaline, meteoric, etc.) with incorporation of the interactions between surface and underground water flows, and sediment transformation processes.

>> See CarDIO sheet

JIP AQUARIUS (Architecture and QUAntification of a Reservoir In a lacUStrine system) : understand and quantify the physical properties of carbonaceous reservoirs in a lacustrine system

Following the COMPAS (Cretaceous Outcrop analog from Argentina for microbial Pre-salt Atlantic Series) JIP, the AQUARIUS JIP aims to characterize and evaluate carbonate-rich reservoirs in a lacustrine system with complex architectures and different heterogeneity scales, using the Green River Formation (USA) as an outcrop analog.

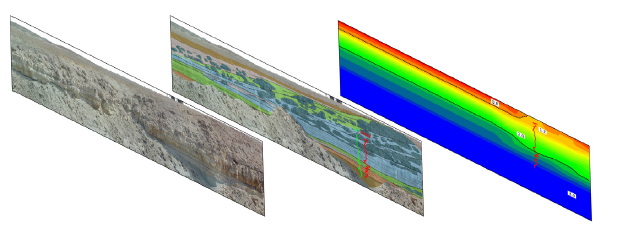

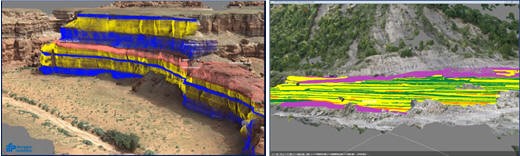

SmartAnalog™ : model 3D outcrops to improve the characterization of complex reservoirs

To understand and correctly describe complex geological reservoirs, SmartAnalog™ provides 3D outcrop modeling, using photogrammetry and interactive visualization techniques. Digital geological outcrop analogs are used as a basis for the geological and geostatic interpretation of reservoirs.

TELLUS : digital transformation serving Earth sciences

The TELLUS solution gives community members the opportunity to explore applications of emerging digital technologies (data science, artificial intelligence, virtual reality, etc.) in the field of geosciences, regardless of the industrial sector concerned.

Members share their usage scenarios, while IFPEN provides scientific intelligence and holds seminars to present the findings.

Each member then has the opportunity to further explore a specific usage scenario through a service or bilateral collaboration with IFPEN.

CUSTOM SERVICES FOR INDUSTRY AND PUBLIC AUTHORITIES

IFPEN offers its expertise in modeling and simulating the underground environment for industry and public authorities, and proposes customized research services.

Studies on well productivity in the presence of gas condensates

In the presence of natural gas condensates, the productivity of oil and gas producing wells falls due to the accumulation of a condensate ring in the vicinity of the well. Oil companies need to understand the reason for this drop in productivity and consider solutions to prevent it and anticipate it.

IFPEN provides reliable well productivity forecasts supported by laboratory experiments along with advanced and accurate modeling of physical phenomena close to wells. Laboratory experiments are conducted using a unique patented technology, the CAL-X™ high-throughput coreflood test bench. The CooresFlow research software is used to simulate reactive transport.