Wind energy

Wind energy

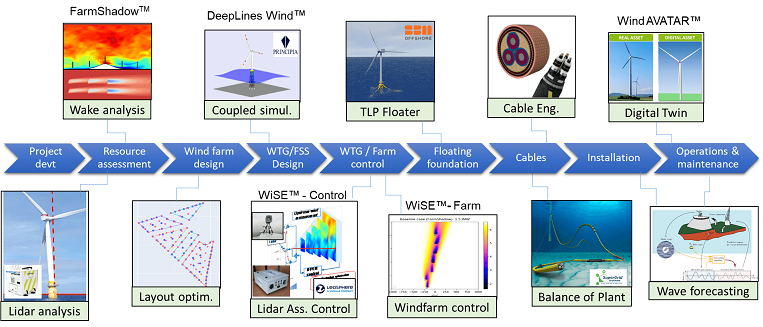

Our solutions

IFPEN develops innovative solutions aimed at facilitating the implementation of new projects and optimizing energy production on both a turbine scale and an onshore and offshore farm scale. Research results are transferred in tools marketed by partners. IFPEN also proposes collaborative research in the form of Joint Industry Projects (JIPs).

Points to remember

GreenWITS, an IFPEN subsidiary created in 2023, provides industrial players with innovative services stemming from research conducted at IFPEN, particularly in the development of physical simulation codes. These services include farm design, the dimensioning of offshore turbine foundations, turbine monitoring and farm control.

IFPEN’s activities in the field of wind energies relate to six priority areas :

- The evaluation and exploitation of the wind resource,

- The development of specific tools for offshore wind,

- Offshore turbine design,

- Underwater cable engineering,

- Wave prediction,

- Turbine and farm control systems,

- Exploitation and maintenance using digital twins,

Evaluation and exploitation of the wind resource

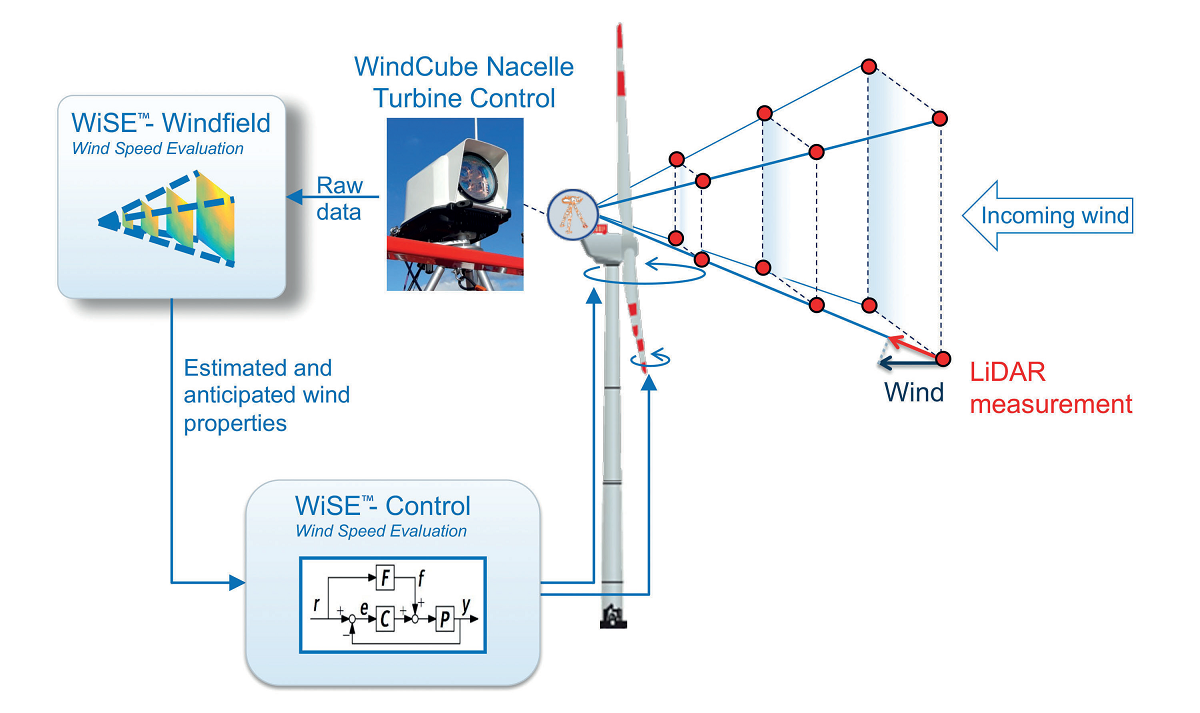

Wind analysis using Lidar

The WiSE™-WindField, tool developed by IFPEN enables the precise 3D reconstruction of the prevailing wind field from raw data gathered via a Lidar placed on a turbine nacelle. This software is integrated into the WindBox optimization solution developed by Vaisala, which improves the performance of turbines by controlling wind disturbances, the aim being to extend their operating life and reduce costs.

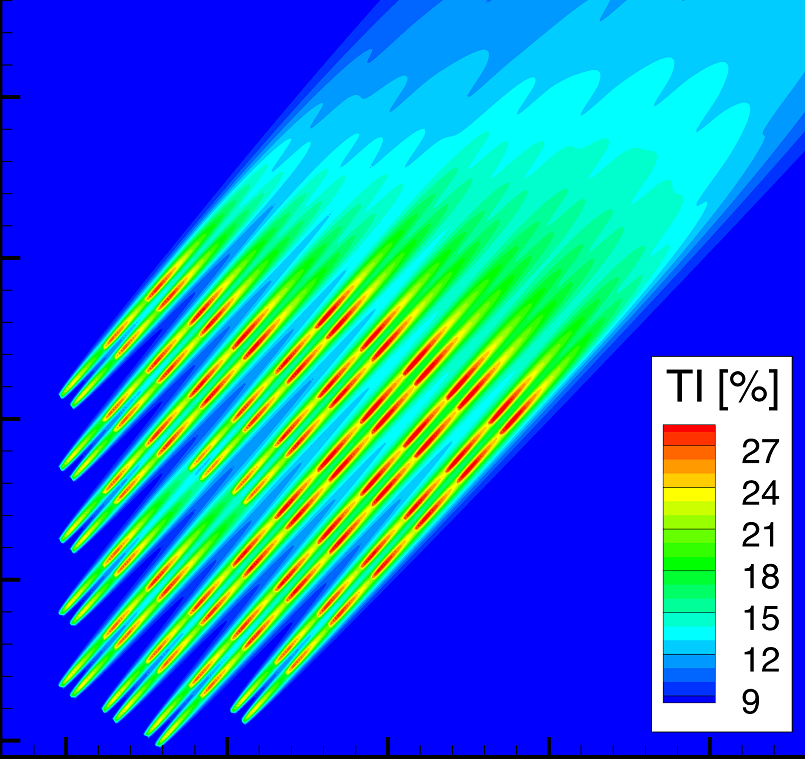

Wake simulation

IFPEN has an internal tool for the rapid modeling of the wake effects caused by interactions between turbines. This modeling can be directly applied to the industrial context.The loss of energy associated with wake effects is typically between 10 and 20% on a wind farm compared to single wind turbines in isolation. Wake also causes an increase in wind turbulence, resulting in an increase in fatigue affecting turbines, as well as fixed and floating foundations located downstream. IFPEN also develops high-fidelity wake simulation tools, particularly within the open-source Meso-NH and waLBerla codes developed by Météo-France and FAU (Erlangen) combining the Large Eddy Scale (LES) turbulence approach with actuator techniques for turbines. The reference simulations obtained are used to verify the field of application of the engineering tool.

Optimization algorithms for wind farm design

IFPEN develops algorithms that make it possible to calculate production losses due to wake affects and automatically optimize the positioning of the various wind turbines relative to one another in order to maximize the energy produced.

The FarmShadow™ software solution was developed within this context with a dedicated optimization strategy. It is based on the state of the art of wake models and is continuously improved by research conducted at IFPEN alongside partners such as Météo France (the French national weather service) or within the framework of the ANR Momenta project.

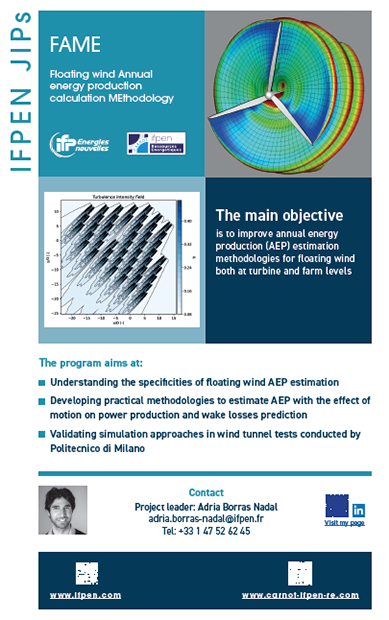

JIP FAME (Floating wind AEP calculation Methodologies): for improved calculation of the annual energy production of floating wind turbines

JIP FAME (Floating wind AEP calculation Methodologies): for improved calculation of the annual energy production of floating wind turbines

The FAME JIP aims to improve AEP (Annual Energy Production) estimation methodologies on two levels: firstly in terms of the floating wind turbine, taking into account the impact of its movement on energy production, and secondly in terms of the farm as a whole, analyzing the impact of the movement of each turbine on wake and thus on interactions between turbines. This work will use simulation tools developed at IFPEN, in particular DeepLinesWind™ for the coupled simulation of a floating wind turbine and MesoNH, as well as FarmShadow™ for the simulation of wake effects. Numerical simulations will be compared with wind tunnel tests conducted by Politecnico di Milano on a reduced turbine model simulating floating conditions.

High-fidelity, high-performance wind farm simulation

IFPEN and Friedrich-Alexander University (Erlangen-Nuremberg, Germany) enhanced the waLBerla platform to adapt it to wind farm simulation within the framework of the EoCoE-II project.

>> Find out more about waLBerla-Wind

Specific tools for offshore wind

The design of offshore turbines and floaters with DeepLinesWind™

Offshore turbines design

In addition to calculating wind and current forces on a floating body and structural deformations, DeepLines Wind™ offers aerodynamic calculation capacities to analyze the effects of wind-on-wind turbine blades, as well as features associated with command control. Bringing these three types of physical analyses together makes it possible to perform combined mechanical simulations of all the wind turbine’s components (blades, tower, floater, anchoring system) using the same software, an obvious advantage compared to the competition.

The performance of DeepLines Wind™ has been demonstrated within the framework of projects conducted by IEA-Wind in partnership with IFPEN, such as theOC4/OC5/OC6 and DANAERO projects. This software is also used in collaborative projects such as the European H2020 HIPERWIND project aimed at improving the incorporation of uncertainties in offshore turbine design, operation and maintenance.

Advanced lifting line aerodynamic models (Vortex methods) that have been optimized in terms of calculation costs are also available in a research version of the DeepLines Wind™ software and accessible in the form of studies proposed by IFPEN.

Floater design

IFPEN conducts multi-physical calculations with Deeplines Wind™ to verify the integrity of different floating turbines throughout their operation (extreme conditions, cyclical component fatigue). By incorporating aero-servo-hydro-elastic analyses within the same code, IFPEN is able to provide reference simulations that can be used to verify simplified approaches that are more operational in an industrial context (e.g., studies conducted separately by turbine suppliers and floater developers).

IFPEN also has a library of optimization and uncertainty management tools that is continuously enhanced by ongoing research. We develop new methods making it possible to optimize within a reliability framework the designs of different floater and anchoring system technologies.

Collaboration with SMB Offshore for innovative floaters

IFPEN, alongside its partner SBM Offshore, designed the highly innovative tensioned line float system chosen by EDF Renouvelables for its Provence Grand Large project supported by ADEME and operational in 2023. IFPEN is pursuing its collaboration with SBM Offshore to design an advanced floater (SBM Float4Wind™) using fewer materials while maintaining the same level of resistance and stability.

Use of the Jean Zay supercomputer to reduce the cost of floating wind turbines

Within the framework of dimensioning studies on the Jean Zay supercomputer, obtained as a result of the GENCI “Grands Challenges” call for projects, IFPEN was able to test the behavior of a floating wind turbine in all of the wind and wave conditions likely to affect a site. The results represent a reference solution to validate new methods for predicting the fatigue life of the structure, thereby saving on simulation costs.

To find out more : IFPEN uses high-performance computing to reduce the cost of floating wind turbines.

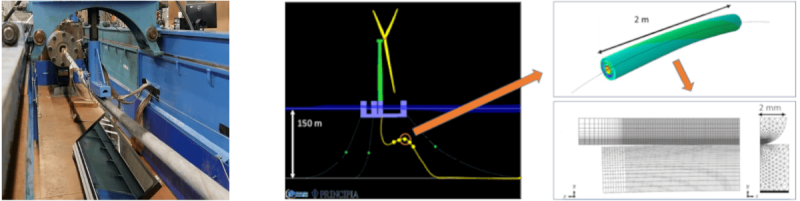

Cable engineering

Cables are essential elements in offshore turbines. A floating turbine is anchored in place using lines that can be made of steel or synthetic cables. In addition, turbines are connected to one another, as well as to the substation and the coast, via electric cables. IFPEN has developed an approach making it possible to improve the prediction of cable fatigue resistance, replacing current empirical criteria with physical multiscale modeling. IFPEN also conducts experimental campaigns in its mechanics laboratory to validate numerical simulations, characterize the non-linear behavior of synthetic cables and, with the LTDS laboratory at the Centrale Lyon engineering school, define fretting-fatigue laws governing steel wires. In addition, IFPEN develops new technologies making it possible to optimize anchoring systems and increase their fatigue life.

Real-time wave forecasting for offshore use

IFPEN develops algorithms for the real-time forecasting of waves and swell using sea surface measurements provided by remote sensors. For example, these algorithms make it possible to predict, from a few seconds to a few minutes in advance, the occurrence of short periods of calm in choppy sea conditions or, in contrast, provide a warning when a series of dangerous waves is imminent. The approach exploits the random Gaussian nature of sea conditions. Measurements may come from an X band radar, a Lidar or a stereoscopic camera. The predictions made have different applications, including improved decision-making for offshore operations. In the case of floating turbines, they can be used to support a model predictive control (MPC) system making it possible to maximize energy production while preventing premature component wear.

Wind turbine and wind farm control

Real-time knowledge of incoming wind provided by lidar enables wind turbine and farm control and production optimization. IFPEN develops various control solutions in this field:

- the WiSE-Control™, tool, which implements control strategies based on lidar measurements and makes it possible to optimize wind turbine production and reduce the stresses exerted on the turbines. This tool is being developed in partnership with Vaisala.

- WiSE-Farm™, a collective farm management system hinged around the minimization of aerodynamic interference between turbines and wake redirection. It is based on the use of models included in FARMSHADOW™ software. By determining the optimal orientation and the most appropriate operating point of each turbine within a farm, this tool makes it possible to increase production and reduce structural stresses, limiting the influence of wake.

Wind turbine exploitation and maintenance

Digital twins for turbine and farm monitoring

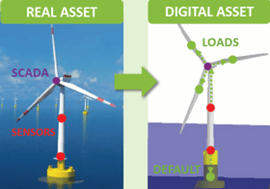

IFPEN develops digital twins to improve the identification of potential turbine anomalies, monitor turbine wear, predict the lifespan of their components, detect decreases in electricity production and, ultimately, optimize production and maintenance.

By optimally combining data fed back from an operating turbine (SCADA- Supervisory Control and Data Acquisition, high-frequency sensors) and physical modeling, the digital twin offers a clear picture of its operating condition (forces exerted, vibratory behavior, etc.) and will flag any anomalies detected.

JIP WIND AVATAR : Digital twins of floating offshore wind assets

Launched in 2023, the objective is to develop a floating offshore digital twin, combining a multi-physical simulator for the dynamic behavior of the structure and metamodels derived from data science and replacing this simulator at lower cost. The prediction of the unmeasured quantity of interest is made with an uncertainty reduction via calibration of the model with structural data.